Top 5 Challenges Mechanical Project Managers Face

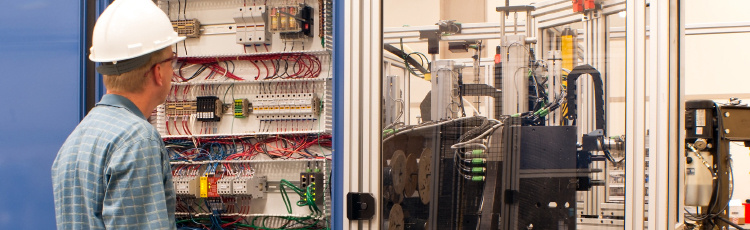

Mechanical project managers oversee high-stakes projects across industries such as construction, energy, mining, manufacturing, and utilities. They ...

ReadGet help with your labeling project with resouces from DuraLabel! Find solution based on job or industry type, or check out all guides, articles, and more. Look into case studies to see how DuraLabel products have help customers like you.

Mechanical project managers oversee high-stakes projects across industries such as construction, energy, mining, manufacturing, and utilities. They ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

HVAC Installation Done Right: 8 Essential Tips to Prevent Costly Mistakes

Read

A workplace safety incident can have far-reaching consequences. In an instant, operations can grind to a halt, injuries can change lives, and ...

Read

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical as the first. Systems are in place, ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

As businesses across the country continue to focus on workplace safety and regulatory compliance, a straightforward solution is gaining increased ...

Read

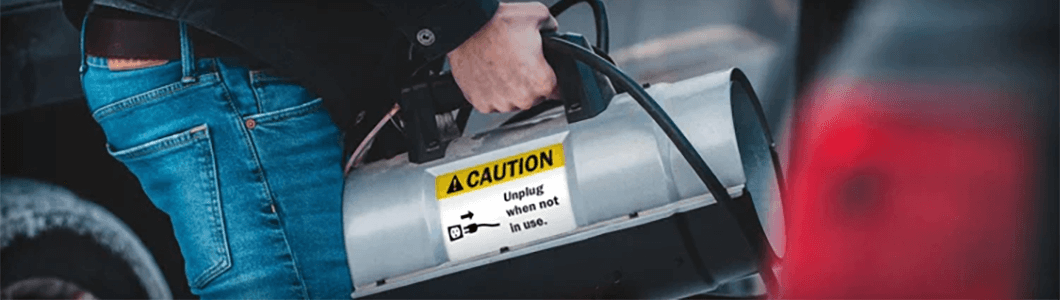

Labels play a critical role in maintaining workplace organization, safety, and compliance. The Bureau of Labor Statistics (BLS) reported 22,049 ...

Read

Aircraft components, parts, and equipment often face extreme weather conditions, including high altitudes, temperature fluctuations, humidity, and ...

Read

With today�s technological advancements, much of the work force is searching for ways to become more efficient in their workplace, whether it�s ...

Read

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the ...

Read

Efficiency is essential for productivity, safety, and smooth operations in any workplace. One often-overlooked way to enhance performance is through ...

Read

A Comprehensive Guide for Pharmaceutical Companies In the realm of pharmaceutical research and development, maintaining a safe and compliant ...

Read

Maintaining safe medical facilities starts with effective hazard communication (HazCom). The Globally Harmonized System of Classification and ...

Read

In the regulatory-driven healthcare environment, proper chemical labeling is required to ensure safety and compliance. The complexities involved in ...

Read

?In February 2023, the Federal Aviation Administration (FAA) issued a?Safety Call to Action?to take a critical look at the U.S. aerospace system�s ...

Read

Mining companies cited years ago have not been paying their fines, and the Mine Safety and Health Administration is clamping down. MSHA officials say ...

Read

In demanding industrial environments, time is money�and mistakes can be costly. Whether it is keeping workers safe or staying compliant with ...

Read

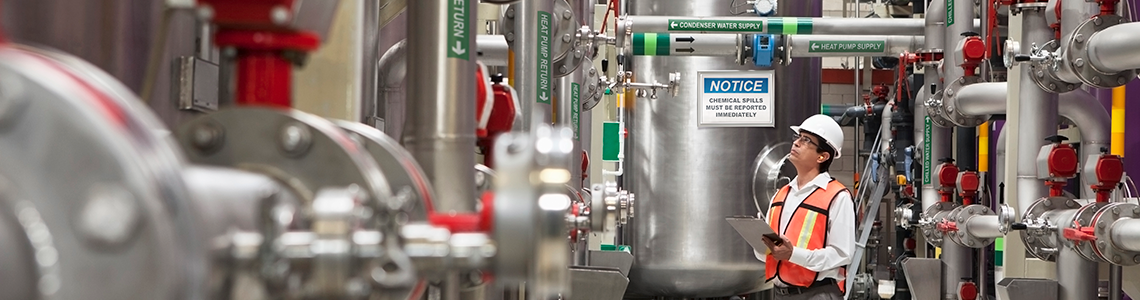

Managing a complex facility comes with the challenge of keeping everything running smoothly while staying compliant with safety standards. In the ...

Read

Ensuring the safety and efficiency of an aviation facility relies heavily on the quality and effectiveness of its safety labels and signs. Operations ...

Read

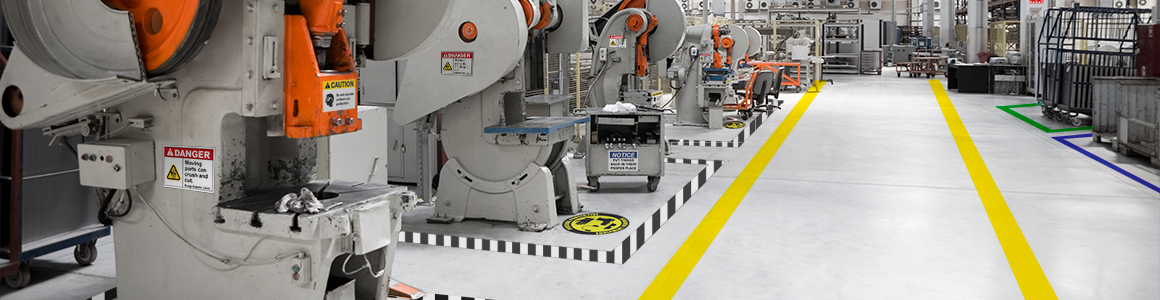

Manufacturing facilities require a delicate balance of precision, speed, and safety. Effective communication ensures smooth operations and protects ...

Read

In February 2023, the Federal Aviation Administration (FAA) issued a?Safety Call to Action?to take a critical look at the U.S. aerospace system�s ...

Read

Ineffective or missing fall protection has been the Occupational Safety and Health Administration's (OSHA) most-cited violation for more than a ...

Read

It is important to consider the hidden dangers that might be lurking within workplace electrical systems. Ground faults, which are often overlooked, ...

Read

The U.S. Bureau of Labor Statistics (BLS) shared its workplace fatality statistics for 2022. The bureau reported 5,486 fatal work injuries in the ...

ReadLogistics involves managing the movement of resources. This not only includes products, but the movement and storage of materials, tools, equipment, ...

Read

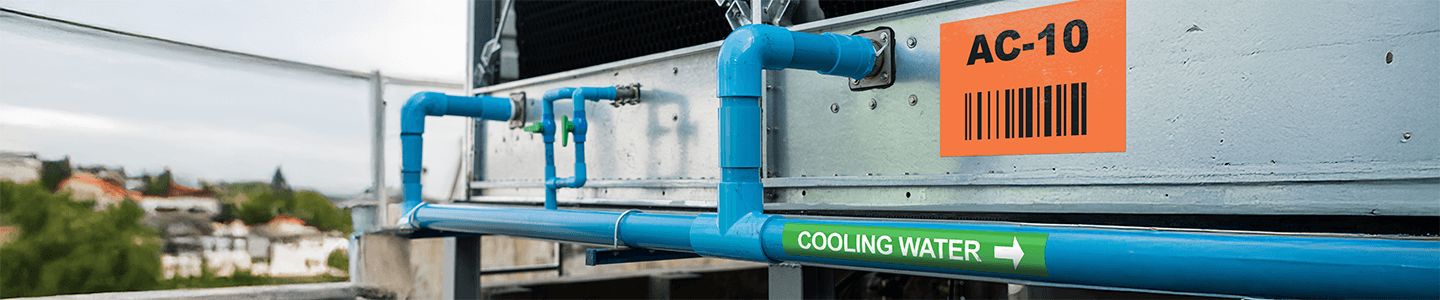

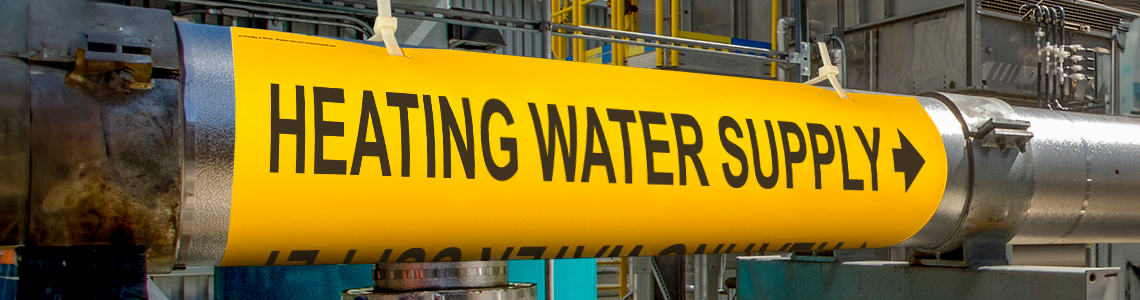

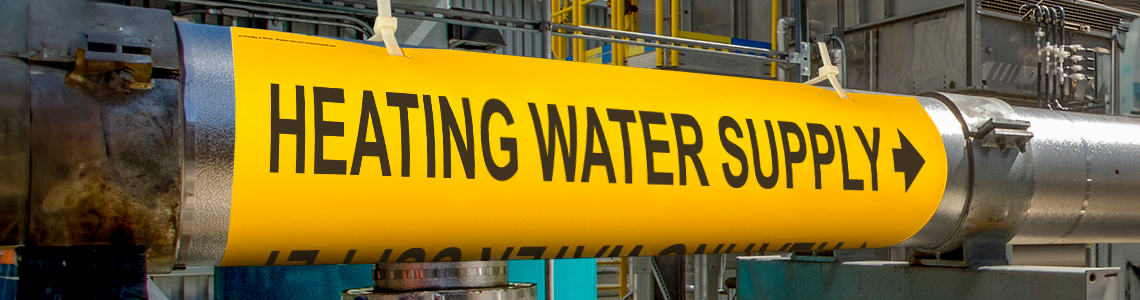

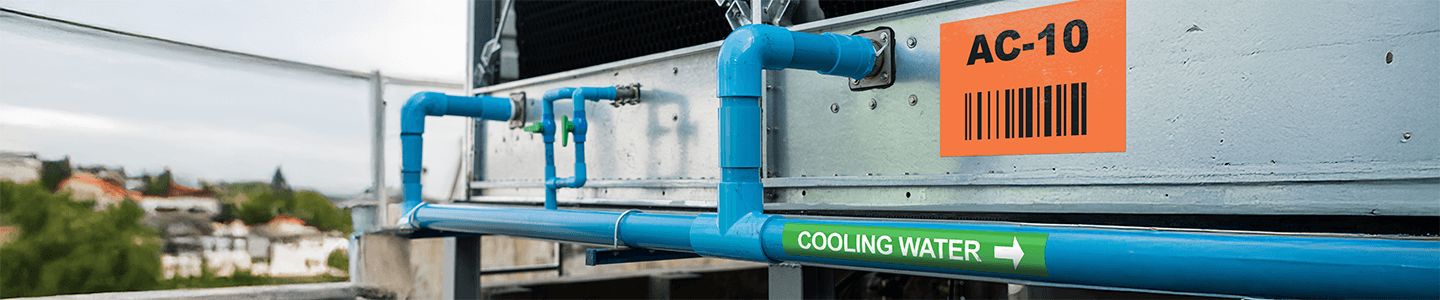

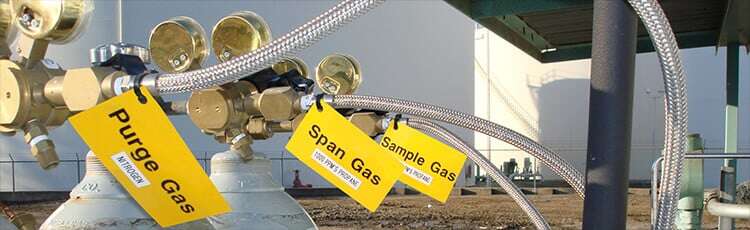

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational efficiency. Stocking the correct sizes, shapes, ...

Read

Solar installations are becoming common as renewable energy sources gain traction worldwide. However, like any electrical system, solar installations ...

Read

As a safety manager, leveraging your site safety committee effectively can transform your workplace environment. Here is a guide on safety ...

Read

Occupational Safety and Health Administration (OSHA) regulations are constantly evolving to improve workplace safety. Recently, OSHA updated its ...

ReadFire safety is a top concern for businesses of all sizes. The U.S. Fire Administration (USFA) reported that the 2022 national estimates for ...

Read

In compliance with the Small Business Regulatory Enforcement Fairness Act (SBREFA), OSHA assembled an SBAR Panel on August 25, 2023. The Panel ...

Read

Traditional approaches to safety training, while effective, often struggle to maintain engagement and enthusiasm among employees. Enter ...

Read

At DuraLabel, we are committed to providing safety solutions that are durable, reliable, and rigorously tested for compliance in the toughest ...

Read

From workplaces and public spaces to transportation hubs and construction sites, the presence of clear and comprehensible safety signs in multiple ...

Read

Wearable technology is a transformative solution, offering real-time monitoring, communication, and support that redefine workplace safety standards. ...

Read

One of the most pressing challenges companies face is the shortage of skilled labor. As organizations strive to maintain productivity and quality in ...

Read

Staying current with compliance standards is not only crucial but also a fundamental responsibility for safety professionals. The ever-evolving ...

Read

When we think about workplace accidents, it�s hard not to think about the most dramatic, worst-case scenarios like fires, amputations, or forklift ...

Read

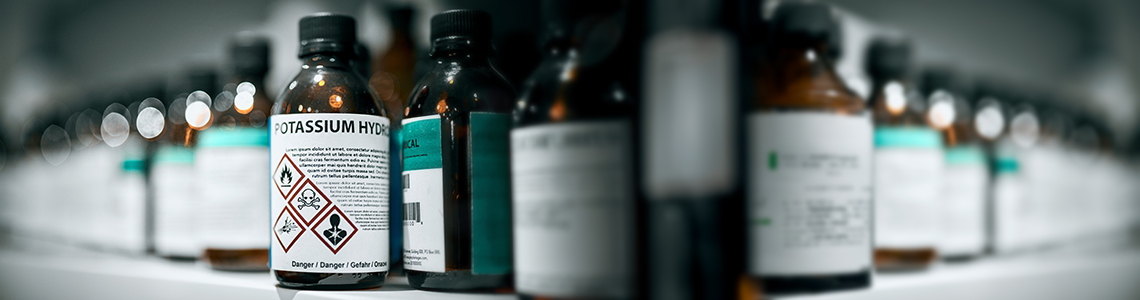

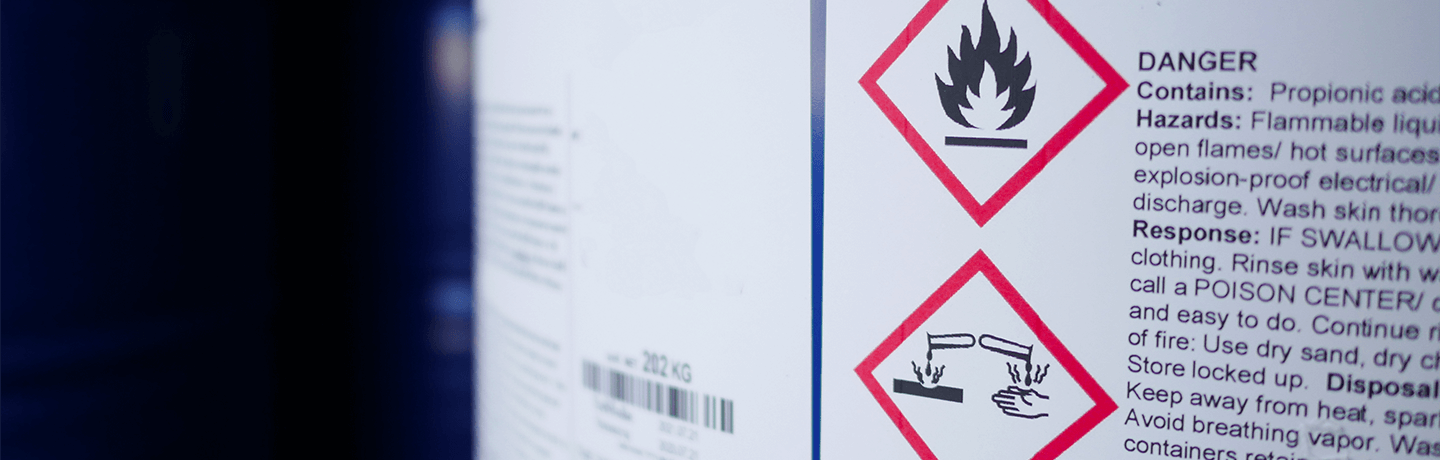

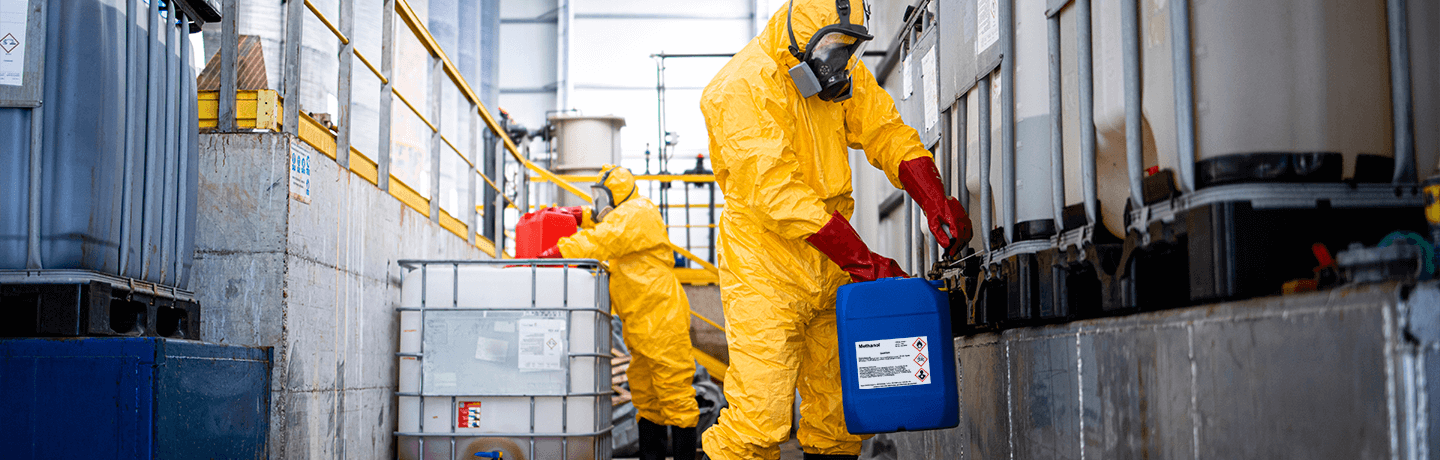

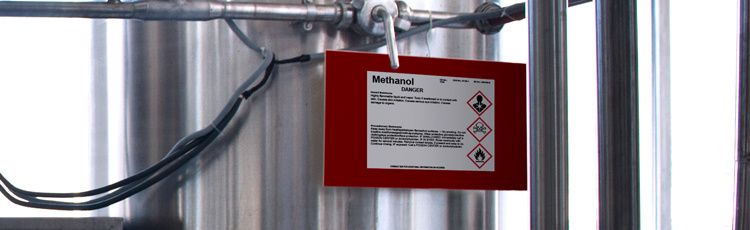

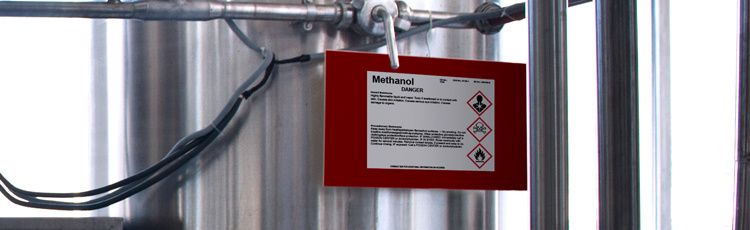

Dealing with dangerous substances is a major concern for any workplace. Whether it's chemicals that can burn your skin or gases that can catch fire, ...

Read

There are a lot of different hazards in the modern workplace. Between moving parts, vehicle traffic, ledges, low visibility, and pedestrian safety, ...

Read

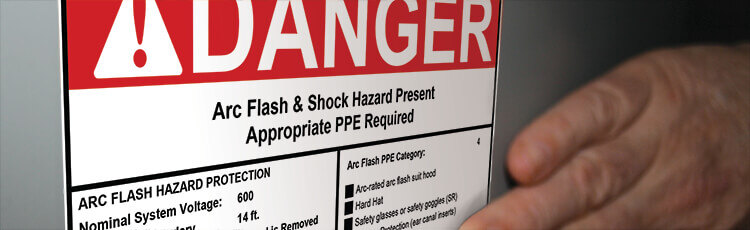

Arc flash is not something to take lightly. The dangers of arc flash can cause severe damage to a person and the surrounding area. Sadly, it is still ...

Read

A Spotlight on Safety: National Electrical Safety Month Every year as we transition through the seasons, we never really stop to think about how much ...

Read-1.png)

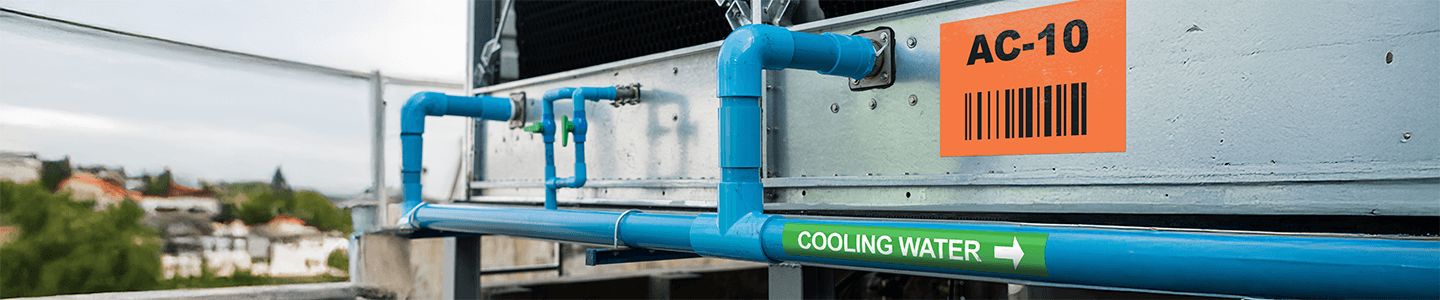

Directional pipe markers are key when it comes to effectively identifying a facility�s pipe system. These markers are vital communicators that safely ...

Read

Understanding Arc Flash Arc flash incidents are among the most hazardous risks faced by personnel working with or around electrical equipment. These ...

Read-1.png)

What Are Toolbox Talks? Toolbox Talks, short safety meetings typically held at the job site before the commencement of a workday, are instrumental in ...

Read

In refrigeration and HVAC, it's out with old, complex systems and in with new, efficient ammonia systems. When working with low-charge ammonia ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

Navigating the occupational safety and health environment can feel like wading through a minefield. When dipping your toes into regulations, a vital ...

Read

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and compressed air, which is crucial to ...

Read

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and compressed air, which is crucial to ...

Read

Work zones are essential to maintaining and upgrading our roadways. Unfortunately, these zones can create havoc for travel commutes and create safety ...

Read

It's important to note that workplace safety is not just about meeting compliance but approaching safety comprehensively. This ensures employees ...

Read

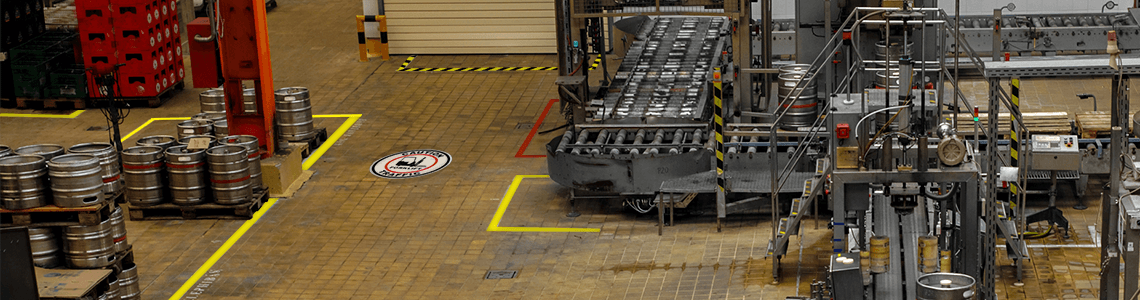

In today's industrial workforce, workers must know how to navigate through many obstacles often including traffic and complex facilities. Floor ...

Read

Brain Injury Awareness Month Every year, the Brain Injury Association, the nation�s oldest and largest brain injury advocacy organization, raises ...

Read

What Problems Does Floor Marking Address? Floor marking is the process of using tapes, paints, or other visual indicators to prevent accidents and ...

Read

Floor marking tape is designed to inform workers when they are approaching a safety hazard. OSHA requires that all walking and working surfaces be ...

Read

Modern warehouses experience a wide variety of traffic ranging from forklifts and pedestrians to large tractor-trailer rigs, pickup trucks, and cars. ...

Read

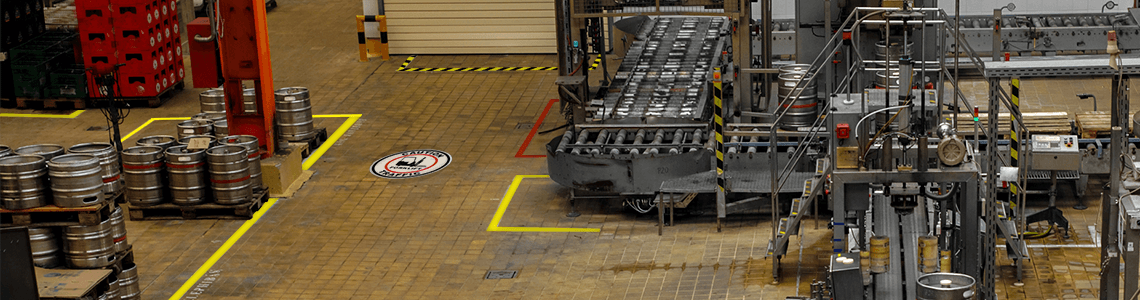

Hold My Beer: 5 Floor Marking Tips from a Brewery In the heart of the brewery, every step is important for the perfect pint. To keep things running ...

Read

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To make sure each facility gets the most out ...

Read

Budget-Friendly Protection: Smart Tips to Maximize Safety Without Breaking the Bank In order to implement any new plan, it often costs a pretty penny ...

Read

As the temperatures continue to drop and the frost sets in, the realization that winter is here has become clearer. The question of safety signs, ...

Read

A Guide to 5S in Medical Facilities for Visual Communication Creating a robust visual communication system is pivotal for the success of any medical ...

Read

In the hustle and bustle of the workplace, it's easy to overlook potential hazards that can lead to injuries or, in extreme cases, fatalities. ...

Read

Ensuring a safe and secure work environment is a shared responsibility that each one of us plays a crucial role in. However, never assume that ...

Read

From Fear to Empowerment: How OSHA's Free Consultation Transforms Workplace Safety In the realm of workplace safety, the mere mention of an OSHA ...

Read

Breaking Barriers: Women Shatter Stereotypes in Health and Safety The lack of gender diversity is an issue for many industries, and changing this has ...

Read

Top 10: OSHA Violations for 2023: Stay Compliant & Safe In the realm of occupational safety, staying abreast of the latest developments is ...

Read

In an industry that is often fast-paced, where the possibilities go beyond the traditional office setting, the demand for a field printer becomes a ...

Read

In the sprawling landscapes of industrial facilities, warehouses, and manufacturing plants, effective wayfinding is essential for optimizing ...

Read

Workplace safety is not only crucial for protecting employees' well-being but also for the overall success of a business. Employers who invest in ...

Read

There are 12,900 worker-related injuries every day, according to the National Safety Council, and this equates to one injured person every 7 seconds. ...

Read

Workplace injuries are common occurrences. There are 12,900 worker-related injuries every day, according to the National Safety Council, and this ...

Read

In the world of industrial labeling solutions, one size certainly does not fit all. Different businesses and industries have unique label printing ...

Read

Safety is an essential aspect of any workplace. To ensure the well-being of employees and comply with regulations, businesses must implement ...

Read

It is no secret that noise plays a factor in day-to-day industrial manufacturing. Unfortunately, it is also one of the most pervasive occupational ...

Read

In an industry that is often fast paced, where the possibilities go beyond the traditional office setting, the demand for a field printer becomes a ...

Read

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing essential safety information. In environments ...

Read

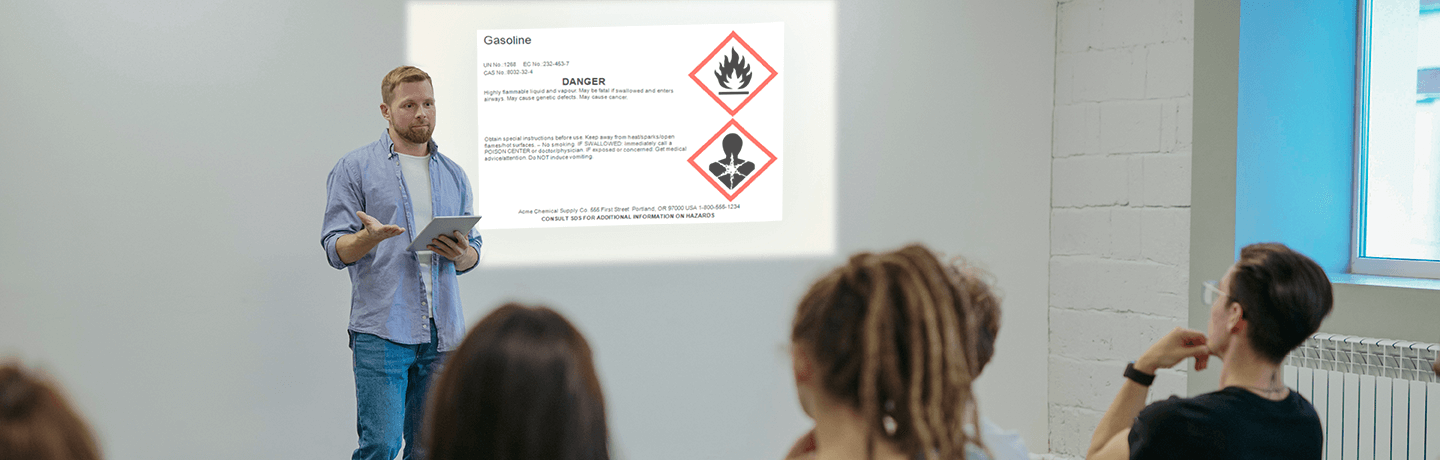

In today's industrial landscape, workplace safety and chemical hazard communication are paramount. The Globally Harmonized System of Classification ...

Read

The sounds of blaring horns and alarms fill your ears. Nothing is more insufferable or uninspiring than seeing the same boring signage every day or ...

Read

Creating compliant Occupational Safety and Health Administration (OSHA) safety signs is a crucial element in the overarching mission of fostering a ...

Read

Arc flashes are a dangerous electrical phenomenon that can occur in intense voltage areas and are more common than most people realize.

Read

A routine maintenance task is in progress, and as the technician attempts to tighten a loose connection on a panel, a blinding flash of light erupts. ...

Read

Barcode labeling is an essential aspect of warehouse management. It helps to track inventory, reduce errors, and improve efficiency. Barcode labeling ...

Read

Organizations are required under the OSHA General Duty clause to provide a working environment "free from recognized hazards that are causing or are ...

Read

Floor marking and signs in industrial environments are a cost-effective way to increase safety compliance, visibility, and organization for ...

Read

Creating a safe work environment requires more than just following rules and providing training. It necessitates the active involvement and support ...

Read

Whether by force of nature or unfortunate accident, disasters can strike at any moment. In the workplace, disaster preparedness is crucial to ensure ...

Read

In the face of declining sales and profits during the 1950s, Eiji Toyoda began looking for ways to improve Toyota's manufacturing processes. He ...

Read

Curtis Weber is from a monochromatic landscape where the Canadian sky blends into the rolling fields, where the horizon is only interrupted by grain ...

Read

1,008 construction workers were killed in workplace accidents in 2020, 21% of all fatal occupational injuries. 368 from slips, trips, and falls 247 ...

Read

The undisputed champion continues its streak with year 12 at the top of the list. The standard outlines when and where fall protection is required ...

Read

71% believe their employers are not following through on safety promises

Read

450,000 people suffer burn injuries each year . Burns account for 42% of all workplace injuries . 20% of workplace burns result in hospitalization. ...

Read

Safety is an essential element of any facility's success. The real challenge is how to maintain productivity levels while not compromising safety ...

Read

As the calendar rolls over to 2023, sites that resolve to make safety a priority will have some new rules and regulations to incorporate. The Spring ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

With today�s technological advancements, much of the work force is searching for ways to become more efficient in their workplace, whether it�s ...

Read

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the ...

Read

Efficiency is essential for productivity, safety, and smooth operations in any workplace. One often-overlooked way to enhance performance is through ...

ReadLogistics involves managing the movement of resources. This not only includes products, but the movement and storage of materials, tools, equipment, ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

A Guide to 5S in Medical Facilities for Visual Communication Creating a robust visual communication system is pivotal for the success of any medical ...

Read

In the face of declining sales and profits during the 1950s, Eiji Toyoda began looking for ways to improve Toyota's manufacturing processes. He ...

Read

Safety is an essential element of any facility's success. The real challenge is how to maintain productivity levels while not compromising safety ...

Read

There are more than 4.2 million material movers in the U.S., most of which work in transportation and warehousing. In 2022, 19 loading dock accidents ...

Read

Lean has been around for decades, but it still has its place as businesses evolve and retain vitality. Big companies' lean plans prove workers can be ...

Read

Recall that the reason for holding safety stock is variation. Variation of lead time, variation of demand, variation of supply, variation of quality, ...

Read

Planned maintenance is a proactive approach to maintenance in which maintenance work is scheduled to take place on a regular basis. The type of work ...

Read

Staying on top of operational efficiency is an ongoing challenge. The lean 5S methodology is a powerful process that helps establish organization, ...

Read

With a rampant rise in injuries from mining haulage equipment, MSHA and others are stepping up education, training, and other safety systems. With ...

Read

What Is a Pull System? A pull system is a lean manufacturing strategy used to reduce waste in the production process. In this type of system, ...

Read

Each year, nearly 80,000 private sector administrative workers suffer on-the-job injuries. With June named by the National Safety Council (NSC) as ...

Read

There is more to implementing Kaizen than we can include on a single web page. However, the following serves as an overview of introducing Kaizen ...

Read

When it comes to workplace improvement, it is almost second nature to think of lean manufacturing tools like Kanban, Total Productive Maintenance, ...

Read

As robotic workers join the warehouse industry, it is important to have safety signs and other communication to help protect the human workers who ...

Read

Lean Healthcare Quality and Safety Healthcare professionals have a long history of caring for their patients and improving the quality of their ...

Read

What is Lean Kaizen? From the corner office to the production floor, Kaizen requires all employees to be involved in making improvements to their ...

Read

What is Lean Maintenance? Lean manufacturing is arguably the single greatest advance in plant efficiency during the past 50 years. Lean has helped to ...

Read

Improving manufacturing efficiency requires eliminating waste. What is waste? Anything that is not adding value to the product or service. This value ...

Read

Businesses continue to turn towards lean manufacturing tools to find ways to tighten their belts and remain competitive. Lean tools with low up-front ...

Read

Staying on top of operational efficiency is an ongoing challenge. The lean 5S methodology is a powerful process that helps establish organization, ...

Read

The Alamodome is a five-tier stadium in the center of San Antonio, Texas. As well as holding pro soccer matches, NFL football games, and WWE, it's ...

Read

Employees should be able to find their way safely and efficiently around the workplace. When crucial signage and other visual cues are amiss, it can ...

Read

What is Continuous Improvement? Continuous improvement is a philosophy of looking to improve products and processes. The greatest effort is spent on ...

Read

The world's largest publisher of private business standards and requirements now offers a written program to help you improve your environment and ...

ReadThis is a Japanese phrase meaning 'go and see for yourself,' which is a central pillar of the Toyota Way, the famous management system adopted by the ...

Read

Staying on top of operational efficiency is an ongoing challenge. The lean 5S methodology is a powerful process that helps establish organization, ...

Read

Compared to writing a business plan, which can take several weeks or months, you can outline multiple business models on a canvas in one afternoon. ...

Read

A list of safety supplies and other gifts that keep on giving for EHS managers. The holidays are here. Shopping yet for your favorite EHS manager? ...

Read

If you are familiar with lean manufacturing principles, you know that lean manufacturing is about eliminating waste. This typically results in ...

Read

Workplace safety is more important than ever before. With federal rules and regulations in place and always changing, it's vital to run a workplace ...

Read

Warehouses are busy work environments. Keep loading dock workers moving efficiently and safety using these tips: 25% of all industrial accidents ...

Read

The House of Lean is a useful tool that can help you understand the order in which lean should be implemented. A "house" is used because it ...

Read

What is a 5S Implementation Team? Lean manufacturing has changed the shape of businesses, improving processes for the better. 5S implementation ...

Read

The 5S system is a lean manufacturing tool that helps to clean and organize the workplace, as well as improve how things are done through ...

Read

TPM Implementation Total Productive Maintenance (TPM) is a continuous improvement program that focuses on improving the equipment in the production ...

Read

At its most fundamental level, 5S is about eliminating waste and getting a facility cleaned up and organized. This includes establishing a storage ...

Read

At its core, "obeya" (Japanese for "big room" or "great room") is a lean manufacturing tool, in which a dedicated room is set aside for employees to ...

Read

Why the Food Industry is Going Lean The food industry is vast and serves hundreds of millions of people each year, more than any other industry. The ...

Read

What is a Periodic Inventory System? A periodic inventory system is an accounting method in which the cost of goods sold is determined periodically, ...

Read

Lean Manufacturing Advantages Womack and Jones, in their book Lean Thinking, define lean manufacturing as "a systematic approach to identifying and ...

Read

Communication and training on a routine basis are important in maintaining forklift safety, operating a forklift, and averting potential hazards. ...

Read

The warehousing industry is bustling. Keeping up with demand and within budget are crucial for operational success. Warehouse Flow owner-operator ...

Read

To understand the organizational development process, we first need to know what organizational development is. As Gary McLean writes in his book ...

Read

Success in today's competitive market requires constant innovation and a vision focused on continuous improvement. When first considering continuous ...

Read

Sometimes, it's not smooth sailing after a company goes lean. Kanban is a workflow management method to improve efficiency. See how to correct common ...

ReadQCDSM is a mouthful of an acronym. Once you learn its meaning and apply its principles to your business processes, your company will meet its goals ...

Read

Healthcare reform has placed pressure on hospitals to streamline their practices in the face of shrinking budgets and increasing demands. Budgets are ...

Read

Here are 11 thoughts, words of wisdom and more to help boost and inspire Lean manufacturing. I don't know about you, but when I'm really cooked from ...

Read

Implementing the 5S system in your warehouse will create a leaner, more efficient workflow. But the rewards ripple out much further than that. Thanks ...

Read

Any successful logistics system needs to provide the required materials where and when they are needed. Lean logistics takes this approach a step ...

Read

What is Cross-Docking? At its most basic, cross-docking establishes a speedy, efficient system for unloading inbound shipments, sorting and ...

Read

More businesses are embracing the benefits of dark manufacturing. See how a longtime business uses it and how to reinforce safety for workers. ...

Read

Asset management is a system that helps you track your property and maximize the return on those assets, which includes equipment, tools, vehicles, ...

Read

Having an online presence when it comes to business is more than just having a website. Rebecca Hart of Drive Source International revs-up the ...

Read

Lean is an efficient approach to running a process, business or organization to minimize waste, lower lead times, reduce overhead and the amount of ...

Read

Although they use the same term, a "Kaizen Event" is very different from "Kaizen." While the foundation of Kaizen is making numerous small changes ...

Read

Mitigate disruptions and build for the future using a thorough 5S plan from top to bottom. Focus on securing safety and efficiency using essential ...

Read

What is DFSS (Design for Six Sigma)? Design for Six Sigma (DFSS) is a process for bringing new products to market with a performance of 4.5 sigma or ...

Read

Does your organization struggle with methods to spot and solve problems? Bring underlying issues to light with Value Stream Mapping (VSM). Value ...

Read

There are several terms and phrases used to describe calibration standards: NIST Certificate of Calibration NIST Certificate of Compliance NIST ...

Read

Construction sites can get messy pretty quickly if proper housekeeping is not routinely enforced. Pre and post work assessments can help improve ...

Read

What is the Lean Manufacturing Process? The lean manufacturing process is a method for creating a more effective business by eliminating wasteful ...

Read

Product identification is a broad category of labeling that includes functions such as product traceability, brand protection, and various ...

Read

When organizing and cleaning up work spaces this spring, consider changing up floor marking for safety, efficiency, and clearer communication. You've ...

Read

If your company works with the United States Department of Defense (DoD), you must comply with military labeling standards. The Item Unique ...

Read

Quick Response codes, commonly known as QR codes, are two-dimensional barcodes that can be scanned and interpreted by mobile devices, such as ...

Read

Food manufacturing is continuously improving after a huge nudge from a year of disruption. How is food processing and manufacturing improving for the ...

Read

The International Organization for Standardization (ISO) is the world's largest developer and publisher of international standards for private ...

Read

What Is the 5S System? The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste. There are five steps in ...

Read

Industrial professionals need inventory management solutions that can handle the chaos of yesterday and the promise of tomorrow. We share tips and ...

Read

The Myth of Large-Batch Production Manufacturers of everything from cakes to computer chips have many ways of organizing production to increase ...

Read

The five whys analysis is also known as the why-why chart and root cause analysis. As these names imply, the purpose is to find the true root cause ...

Read

The 8D methodology (8D=eight disciplines) was developed in Ford Motor Company in the mid-1980s to be used by their suppliers to improve the ...

Read

The quality circle originated in Japan in the early 1960's. The objective was to give the responsibility for identification and resolution of quality ...

Read

You're only strong as your weakest link. While trite, the phrase embodies what manufacturing plants and processing facilities have worked to overcome ...

Read

The integration of Industry 4.0 technology is fast becoming a component of lean manufacturing. Learn how companies are building a solid safety and ...

Read

Manufacturing industries face pressure from both the public and private sectors, each demanding faster, cheaper, and higher-quality products with the ...

Read

The Process Cycle Efficiency, sometimes referred to as the "Value Added Ratio," is a measurement of the amount of value-added time in a process. The ...

Read

Gemba is one of the key principles of lean manufacturing and the Toyota Production System. Gemba is roughly translated from the Japanese as the real ...

Read

Performance is the level of achievement reached under defined conditions. Performance improvement means achieving those results more efficiently, ...

Read

Production leveling, also known as heijunka, is a technique for improving efficiency in multi-step production processes. It forms an important part ...

Read

The term "visual factory" refers to an approach to lean manufacturing processes based on visual information throughout the workplace. A 5S visual ...

Read

Creating a Lean Facility The global market places significant pressure on businesses and other organizations to increase efficiency, improve profits, ...

Read

FOCUS PDCA is a management method, developed in the healthcare industry, used to improve processes. Created by the Hospital Corporation of America ...

Read

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S principles. This quality improvement ...

ReadWhen I think of process flow, a parade comes to mind. The floats, marching bands, celebrities waving from sports cars, and giant character balloons ...

ReadAs the name implies, a Lean Six Sigma methodology combines the principles of lean manufacturing ("Lean") with those of Six Sigma. But, why would ...

Read

The Kano Model is a framework than can supplement decisions in the QFD analysis [Quality Function Deployment]. Specifically the Kano Model attempts ...

Read

Arc flash is not something to take lightly. The dangers of arc flash can cause severe damage to a person and the surrounding area. Sadly, it is still ...

Read

A Spotlight on Safety: National Electrical Safety Month Every year as we transition through the seasons, we never really stop to think about how much ...

Read

Understanding Arc Flash Arc flash incidents are among the most hazardous risks faced by personnel working with or around electrical equipment. These ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

Arc flashes are a dangerous electrical phenomenon that can occur in intense voltage areas and are more common than most people realize.

Read

A routine maintenance task is in progress, and as the technician attempts to tighten a loose connection on a panel, a blinding flash of light erupts. ...

Read

Curtis Weber is from a monochromatic landscape where the Canadian sky blends into the rolling fields, where the horizon is only interrupted by grain ...

Read

The undisputed champion continues its streak with year 12 at the top of the list. The standard outlines when and where fall protection is required ...

Read

An arc flash is an explosive burst of heat and light, caused by a sudden, uncontrolled electrical arc (or current passing through the air). ...

Read

Electrical panels are an integral part of large and small facilities throughout the United States. The panels control the energy that keeps machines ...

Read

Electrical workers consider shocks as part of their job and normal, according to a study. However, it could signal that workers lack safety training. ...

Read

With YouTube and other video-sharing websites, an unimaginable number of videos on just about any subject can be accessed by anyone. In this article, ...

Read

Everyone knows arc flash is dangerous and the hazards that come with electrical work. However, sometimes simple mistakes are made, which can be ...

Read

Workplace safety is more important than ever before. With federal rules and regulations in place and always changing, it's vital to run a workplace ...

Read

What is NFPA 70E? NFPA 70E, or the NFPA's Standard for Electrical Safety in the Workplace, outlines specific practices to be followed in protecting ...

Read

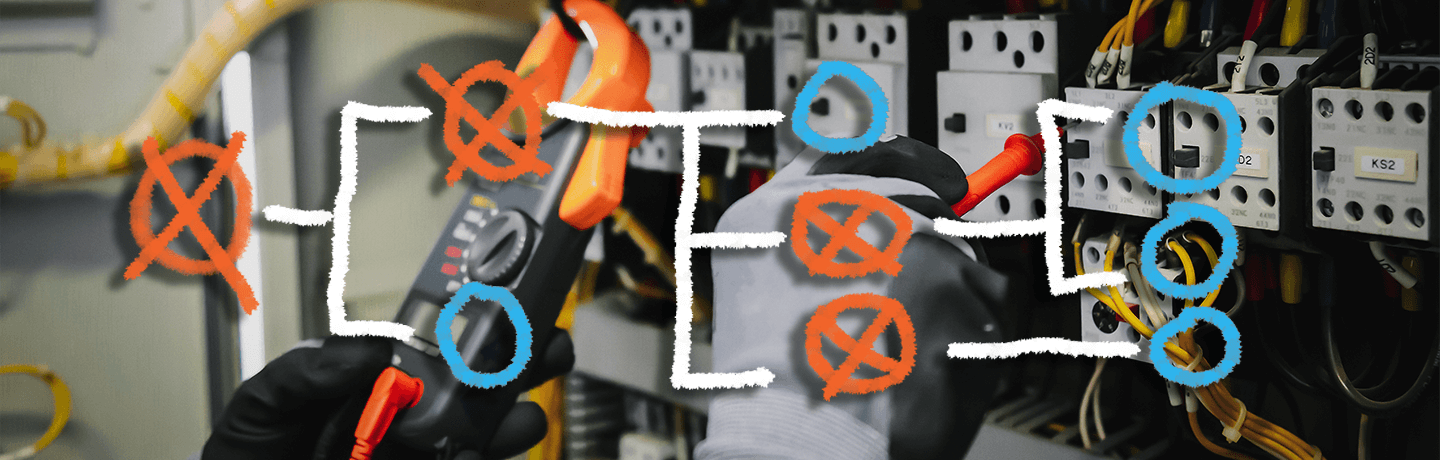

In the modern workplace, electricity is a driving force. Motors, ovens, presses, and mills can all be powered by electricity, and many industrial ...

Read

Never underestimate the power of electricity. While it is easy to take energy for granted, there are many hazards that await workers who do not ...

Read

In this day and age, businesses the world over are placing a premium on dependability. With so many interconnected systems and high-tech advances, ...

Read

There is no harm in double-checking work for safety, especially after an electrical installation. Here are several tips to help support safe ...

Read

Personal Protective Equipment (PPE) is the last line of defense against injuries. When it comes to arc flash, PPE is necessary to protect workers ...

Read

Machines inevitably break down and need to be serviced. It's not enough to just "shut them off" and make repairs. According to the Occupational ...

Read

There are hundreds of detailed resources on electrical safety. Most of them are written by (and for) electricians. But electricity is a part of daily ...

Read

Electrical work is dangerous and causes numerous injuries and deaths per year. Workplaces can take the time to re-evaluate electrical work ...

Read

As part of industrial maintenance, most workers will have had to conduct work inside control system panels. To troubleshoot problems, visual ...

Read

In late December 2016, financial news giant Bloomberg announced they have new data showing that a large shift in global markets has occurred, ...

Read

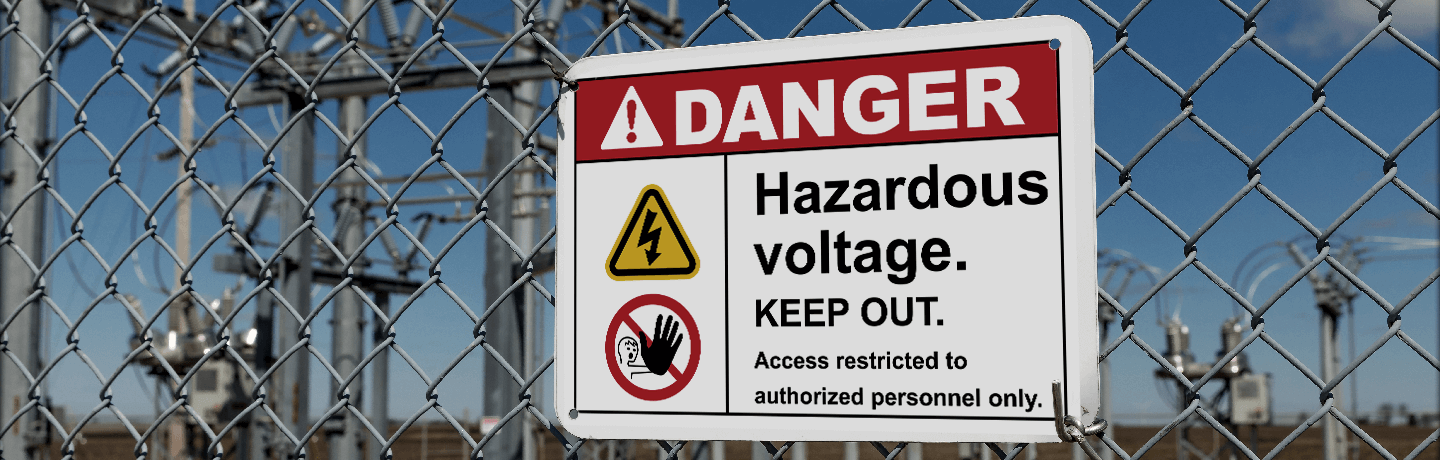

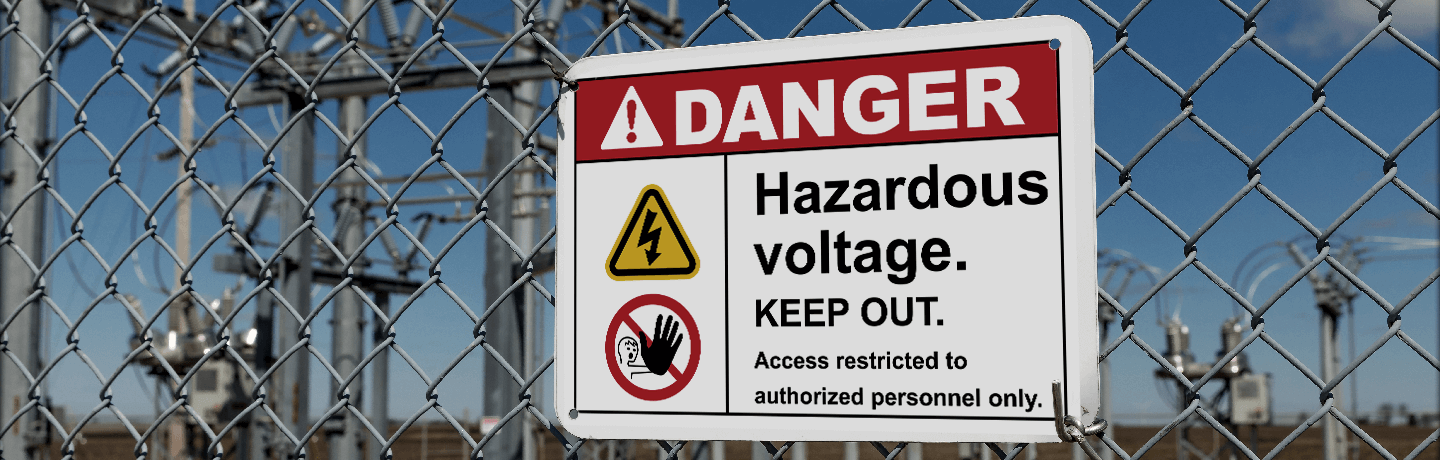

Electrical substations truly have the power. In the wrong hands, that power is dangerous. That's why it's important to ensure safety and security ...

Read

On Thursday, August 12, 2004, electrical contractor Donnie Johnson's day began like any other. However, the looming threat of Hurricane Charlie in ...

Read

NEC 409/UL 508A NEC defines the Short Circuit Current Rating (SCCR) as: "The prospective symmetrical fault current at a nominal voltage to which an ...

Read

Clearly labeled electrical conduit enhances workplace safety, boosts efficiency, and prevents costly mix-ups during maintenance and troubleshooting. ...

Read

No electrical system is without gaps. Often, third parties are best equipped to evaluate existing HSE management systems. We've come a long way from ...

Read

Though simple and effective, lockout/tagout is a frequently violated workplace safety standard. Safety experts from throughout the U.S. talk about ...

Read

Flame retardant coveralls only work if workers put them on before approaching the electrical circuit. Creating a safe environment involves ...

Read

Conducting an arc flash hazard study is the cornerstone for worker safety when working with live equipment and can be improved with the ...

Read

Electrical safety is a major problem in modern workplaces. Each year, OSHA produces a list of their ten most frequently cited violations. General ...

Read

The National Electric Code, or NEC, requires that equipment be marked with the available fault current, and that this labeling be kept up-to-date ...

Read

As your workplace gets more and more wires and cables, it becomes more and more important to know which cord leads where. A network cable plugged in ...

Read

In a recent Facebook poll, electrical workers said that work area and arc flash boundaries were among their top concerns. Here are a few tips to ...

Read

Solar projects are in high demand and so is the solar installation and maintenance workforce. Here are five key safety tips for contractors and ...

Read

NFPA 70E is the major industrial standard for safe electrical work in the United States. It defines three protective boundaries around electrical ...

Read

Each May, the Electrical Safety Foundation International highlights the importance of electrical safety by focusing on ways to educate on the ...

Read

OSHA Signs to Increase Safety in the Electric Power Industry In the high-risk environment of the electric power industry, electrical hazards are ...

Read

When electrical equipment must be maintained or repaired while energized, an arc flash hazard may be present. Affected workers need to know what ...

Read

Understanding Arc Blast: What is a Short Circuit? A short circuit is the flow of current through an unintended path of lower resistance. Short ...

Read

You may be wondering which type of labels you should use for identifying cables and wires. First you need to make sure that when purchasing tags or ...

Read

Very little can happen in mining without electricity. From drilling equipment and powered shovels to fixed and mobile conveyors, most equipment ...

Read

Incident energy is a measurement of energy, usually heat, striking a surface. If you were sitting near a campfire, the warmth you would feel would ...

Read

OSHA's requirements for the control of hazardous energy (typically called lockout/tagout, or LO/TO) are found in 29 CFR 1910.147. These rules require ...

Read

The numbers are staggering: Lockout-Tagout (LOTO) violations are consistently among OSHA's 10 most common violations every year. Without proper LOTO ...

Read

The Role of LO/TO and OSHA Signs in Safeguarding Against Arc Flash In the realm of electrical safety, the risks posed by arc flash incidents loom ...

Read

Electrical hazard violations, including arc flash accidents, were the tenth most common OSHA citation in 2015. Year after year, electrical hazards ...

Read

When workers performing maintenance or repairs on energized electrical equipment, they could be exposed to an arc flash hazard. Where this situation ...

Read

An arc flash is dangerous and has the potential for causing serious injuries. It typically occurs suddenly and without warning - but not without a ...

Read

A fault current is an unintended, uncontrolled, high current flow through an electrical system. Fault currents are caused by very low impedance short ...

Read

The most recent NEC Article 110 had new labeling requirements updated in 2011. The latest labels are for equipment rating purposes. These are not arc ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

Look around you. Is your desk a little cluttered? Is there something nearby that is not necessary for your space? A half-eaten muffin, a few piles of ...

Read

There are a lot of different hazards in the modern workplace. Between moving parts, vehicle traffic, ledges, low visibility, and pedestrian safety, ...

Read

In today's industrial workforce, workers must know how to navigate through many obstacles often including traffic and complex facilities. Floor ...

Read

What Problems Does Floor Marking Address? Floor marking is the process of using tapes, paints, or other visual indicators to prevent accidents and ...

Read

Floor marking tape is designed to inform workers when they are approaching a safety hazard. OSHA requires that all walking and working surfaces be ...

Read

Modern warehouses experience a wide variety of traffic ranging from forklifts and pedestrians to large tractor-trailer rigs, pickup trucks, and cars. ...

Read

Hold My Beer: 5 Floor Marking Tips from a Brewery In the heart of the brewery, every step is important for the perfect pint. To keep things running ...

Read

Industrial floor marking tape is an investment in safety that needs to last to achieve maximum effect. To make sure each facility gets the most out ...

Read

In the sprawling landscapes of industrial facilities, warehouses, and manufacturing plants, effective wayfinding is essential for optimizing ...

Read

Floor marking and signs in industrial environments are a cost-effective way to increase safety compliance, visibility, and organization for ...

Read

Power outages have surpassed the 2013 U.S. average by 30% in the last two years, according to the Department of Energy Information Administration ...

Read

In 2021, local fire departments responded to 1,353,500 fires in the US. That averages out to one every 23 seconds. These fires caused 3,800 civilian ...

Read

Safety isn't the workplace enemy. There are many benefits that come from amplifying safety, and there are tools to make goals successful. Mention the ...

Read

Facility upgrades, expansions, and redesigns have to consider a ton of factors to make them worthwhile and successful. Here are a few tips to getting ...

Read

Employees should be able to find their way safely and efficiently around the workplace. When crucial signage and other visual cues are amiss, it can ...

Read

Whether used as a means to direct traffic, deter vehicle intrusions, and to protect people and structures, bollards act as visual guides, reminding ...

Read

Some of the most common injuries cost employers more than $59 billion a year. We cover the top types of workplace injuries, what causes them, and how ...

Read

Warehouses are busy work environments. Keep loading dock workers moving efficiently and safety using these tips: 25% of all industrial accidents ...

Read

At its most fundamental level, 5S is about eliminating waste and getting a facility cleaned up and organized. This includes establishing a storage ...

Read

Floor marking is a great way to indicate where pedestrian traffic should go. It also is a great way to establish work boundaries and more. A few ...

Read

Communication and training on a routine basis are important in maintaining forklift safety, operating a forklift, and averting potential hazards. ...

Read

The warehousing industry is bustling. Keeping up with demand and within budget are crucial for operational success. Warehouse Flow owner-operator ...

Read

Guests of a haunted house don't typically expect to be completely safe, but safety is a concern for the people trying to scare those who dare to ...

Read

Every day, railroad workers perform maintenance in dark tunnels, maritime employees perform challenging search-and-rescue operations, and truck ...

Read

Great patient care starts with clear visual communication, and hospital wayfinding methods have been proven to be crucial to optimal experiences for ...

Read

National Forklift Safety Day is the second Tuesday in June. The day serves as a focal point for manufacturers to highlight safe use of forklifts and ...

Read

What is Cross-Docking? At its most basic, cross-docking establishes a speedy, efficient system for unloading inbound shipments, sorting and ...

Read

Warehouses are busy work environments. Keep loading dock workers moving efficiently and safely using these tips. Situational awareness is important ...

Read

More businesses are embracing the benefits of dark manufacturing. See how a longtime business uses it and how to reinforce safety for workers. ...

Read

Like the VCR or the ham radio, floor marking paint must now compete with a modern evolution of its function: industrial floor marking tape. We have ...

Read

When employers imagine floor marking, most think of aisle markers, pathway designations, and hazard stripes. However, large floor signs can play an ...

Read

Slips, trips, and falls can seem relatively minor in the grand scheme of things: Who among us, office workers included, hasn't slipped on a puddle in ...

Read

To reduce energy use and costs, some facilities are dimming the lights. However, reducing light can also reduce visibility for workers. Ensure the ...

Read

While the Department of Energy (DOE) works to beef up power grids and make them more resilient, safety professionals and facility managers can shore ...

Read

Forklifts and pedestrians in a busy workplace can sometimes lead to accidents. Yet, there are other important safety assessments that get overlooked. ...

Read

As workplaces grow increasingly sophisticated, it's imperative that employers keep workers safe, increase efficiency, and improve organization. Floor ...

Read

Forklifts play an essential role in warehouses, retail outlets, and other businesses throughout the United States. More than 1,000,000 forklifts are ...

Read

Dangerous working conditions nationwide sparked the creation of the Occupational Safety and Health Act (OSH Act) in 1970. The goal of the OSH Act is ...

Read

When organizing and cleaning up work spaces this spring, consider changing up floor marking for safety, efficiency, and clearer communication. You've ...

Read

What Is the 5S System? The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste. There are five steps in ...

Read

Modern workplaces, however safe they may be, are fraught with hazards. Forklifts, energized equipment, loading docks, busy warehouses, and other ...

Read

The U.S. Bureau of Labor Statistics (BLS) reported to the National Safety Council (NSC) that approximately 15,000 American workers were seriously ...

Read

Companies around the world, from major manufacturers down to your local grocery store, all share a common struggle: efficiently managing the movement ...

Read

The typical construction costs for building an ISO 8 to ISO 7 cleanroom can range from $250 to $1,500 per square foot or more. Many items can drive ...

Read

Slips, trips, and falls make up the majority of general industry accidents 15% of all accidental deaths per year 25% of all reported injury claims ...

ReadUnderstanding the Importance of Proper Storage Proper storage of floor marking supplies is essential for preserving their quality, functionality, and ...

Read

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical as the first. Systems are in place, ...

Read

At DuraLabel, we are committed to providing safety solutions that are durable, reliable, and rigorously tested for compliance in the toughest ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

Create a safer work environment to reduce the likelihood of accidents on any oil and gas industry project using visual communication. Duralabel' ...

Read

Electrical workers consider shocks as part of their job and normal, according to a study. However, it could signal that workers lack safety training. ...

Read

Everyone knows arc flash is dangerous and the hazards that come with electrical work. However, sometimes simple mistakes are made, which can be ...

Read

When it comes to signs in the workplace, opinions vary on why they are necessary and if they even work. One truth, they are required. Here are common ...

Read

Electrical substations truly have the power. In the wrong hands, that power is dangerous. That's why it's important to ensure safety and security ...

Read

On Thursday, August 12, 2004, electrical contractor Donnie Johnson's day began like any other. However, the looming threat of Hurricane Charlie in ...

ReadContractors have to meet many demands and need quality tools to assist in keeping jobs efficient and safe. A general contractor steps onto a ...

Read

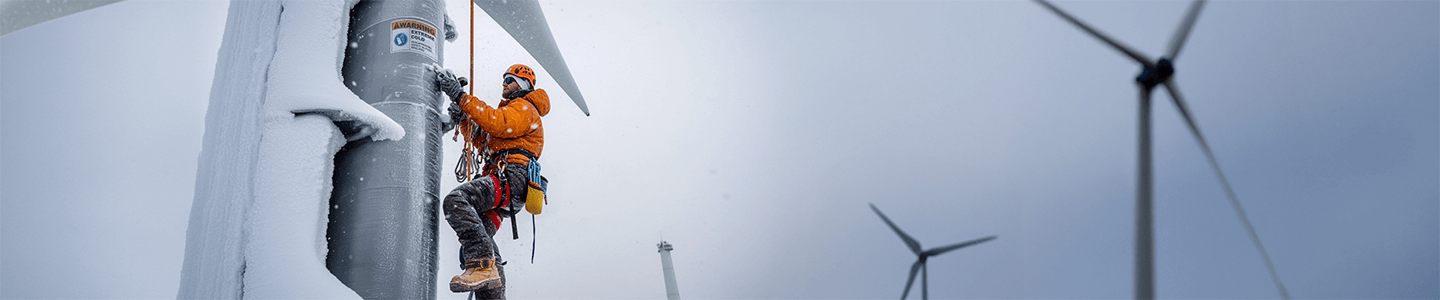

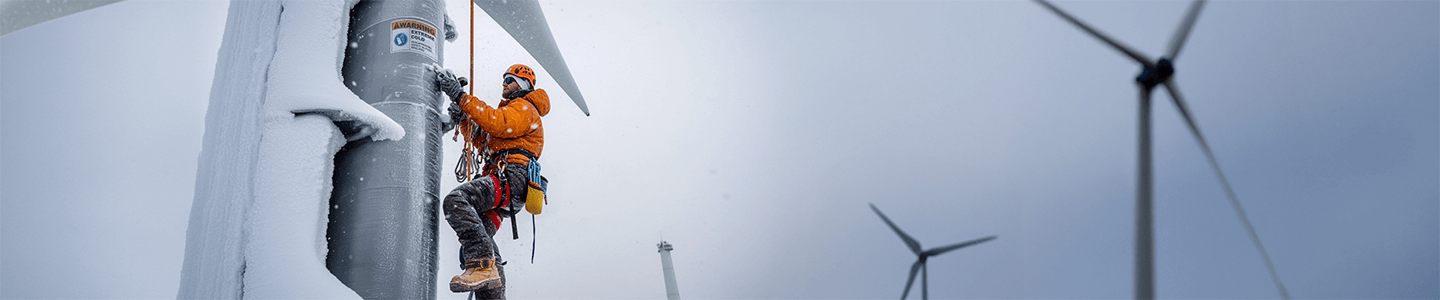

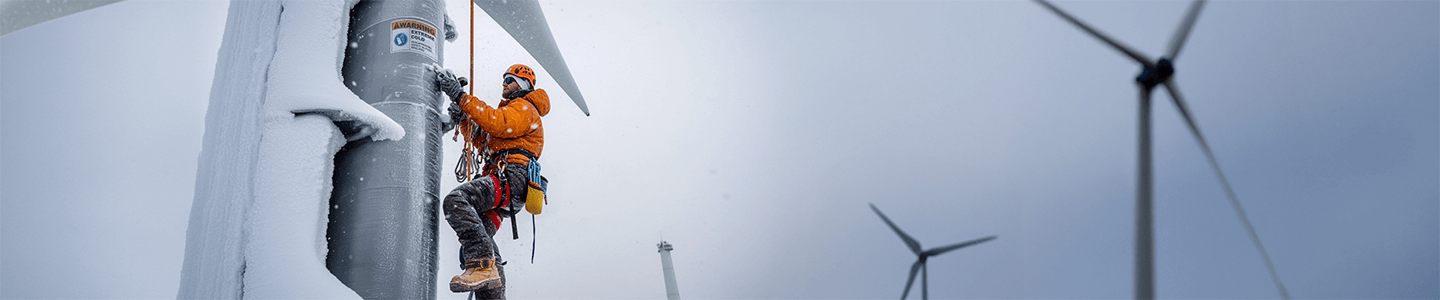

Winter weather brings unique challenges for professionals working in extreme conditions. Tower climbers and wind energy technicians face extreme ...

Read

The Silver Eagle Refinery explosion released a tidal wave of broken glass. Homes were pushed off their foundations and countless workers were burned ...

Read

When a disaster strikes, sometimes our failure to properly label even the simplest piece of equipment or putting off updating an old sign can ...

Read

Military expectations are high when it comes to labeling products for MIL-STD-129 shipping and MIL-STD-130 asset management. Companies contracting ...

Read

Mechanical project managers oversee high-stakes projects across industries such as construction, energy, mining, manufacturing, and utilities. They ...

Read

A workplace safety incident can have far-reaching consequences. In an instant, operations can grind to a halt, injuries can change lives, and ...

Read

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical as the first. Systems are in place, ...

Read

As businesses across the country continue to focus on workplace safety and regulatory compliance, a straightforward solution is gaining increased ...

Read

Labels play a critical role in maintaining workplace organization, safety, and compliance. The Bureau of Labor Statistics (BLS) reported 22,049 ...

Read

Aircraft components, parts, and equipment often face extreme weather conditions, including high altitudes, temperature fluctuations, humidity, and ...

Read

Efficiency is essential for productivity, safety, and smooth operations in any workplace. One often-overlooked way to enhance performance is through ...

Read

A Comprehensive Guide for Pharmaceutical Companies In the realm of pharmaceutical research and development, maintaining a safe and compliant ...

Read

Mining companies cited years ago have not been paying their fines, and the Mine Safety and Health Administration is clamping down. MSHA officials say ...

Read

In demanding industrial environments, time is money�and mistakes can be costly. Whether it is keeping workers safe or staying compliant with ...

Read

Managing a complex facility comes with the challenge of keeping everything running smoothly while staying compliant with safety standards. In the ...

Read

Ensuring the safety and efficiency of an aviation facility relies heavily on the quality and effectiveness of its safety labels and signs. Operations ...

Read

Manufacturing facilities require a delicate balance of precision, speed, and safety. Effective communication ensures smooth operations and protects ...

Read

In February 2023, the Federal Aviation Administration (FAA) issued a?Safety Call to Action?to take a critical look at the U.S. aerospace system�s ...

Read

Ineffective or missing fall protection has been the Occupational Safety and Health Administration's (OSHA) most-cited violation for more than a ...

Read

It is important to consider the hidden dangers that might be lurking within workplace electrical systems. Ground faults, which are often overlooked, ...

Read

The U.S. Bureau of Labor Statistics (BLS) shared its workplace fatality statistics for 2022. The bureau reported 5,486 fatal work injuries in the ...

Read

Solar installations are becoming common as renewable energy sources gain traction worldwide. However, like any electrical system, solar installations ...

Read

As a safety manager, leveraging your site safety committee effectively can transform your workplace environment. Here is a guide on safety ...

Read

Occupational Safety and Health Administration (OSHA) regulations are constantly evolving to improve workplace safety. Recently, OSHA updated its ...

Read

In compliance with the Small Business Regulatory Enforcement Fairness Act (SBREFA), OSHA assembled an SBAR Panel on August 25, 2023. The Panel ...

Read

Traditional approaches to safety training, while effective, often struggle to maintain engagement and enthusiasm among employees. Enter ...

Read

From workplaces and public spaces to transportation hubs and construction sites, the presence of clear and comprehensible safety signs in multiple ...

Read

Wearable technology is a transformative solution, offering real-time monitoring, communication, and support that redefine workplace safety standards. ...

Read

One of the most pressing challenges companies face is the shortage of skilled labor. As organizations strive to maintain productivity and quality in ...

Read

Staying current with compliance standards is not only crucial but also a fundamental responsibility for safety professionals. The ever-evolving ...

Read

When we think about workplace accidents, it�s hard not to think about the most dramatic, worst-case scenarios like fires, amputations, or forklift ...

Read

There are a lot of different hazards in the modern workplace. Between moving parts, vehicle traffic, ledges, low visibility, and pedestrian safety, ...

Read

Arc flash is not something to take lightly. The dangers of arc flash can cause severe damage to a person and the surrounding area. Sadly, it is still ...

Read

A Spotlight on Safety: National Electrical Safety Month Every year as we transition through the seasons, we never really stop to think about how much ...

Read

Understanding Arc Flash Arc flash incidents are among the most hazardous risks faced by personnel working with or around electrical equipment. These ...

Read-1.png)

What Are Toolbox Talks? Toolbox Talks, short safety meetings typically held at the job site before the commencement of a workday, are instrumental in ...

Read

In refrigeration and HVAC, it's out with old, complex systems and in with new, efficient ammonia systems. When working with low-charge ammonia ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

Navigating the occupational safety and health environment can feel like wading through a minefield. When dipping your toes into regulations, a vital ...

Read

Work zones are essential to maintaining and upgrading our roadways. Unfortunately, these zones can create havoc for travel commutes and create safety ...

Read

It's important to note that workplace safety is not just about meeting compliance but approaching safety comprehensively. This ensures employees ...

Read

Brain Injury Awareness Month Every year, the Brain Injury Association, the nation�s oldest and largest brain injury advocacy organization, raises ...

Read

Budget-Friendly Protection: Smart Tips to Maximize Safety Without Breaking the Bank In order to implement any new plan, it often costs a pretty penny ...

Read

As the temperatures continue to drop and the frost sets in, the realization that winter is here has become clearer. The question of safety signs, ...

Read

Ensuring a safe and secure work environment is a shared responsibility that each one of us plays a crucial role in. However, never assume that ...

Read

From Fear to Empowerment: How OSHA's Free Consultation Transforms Workplace Safety In the realm of workplace safety, the mere mention of an OSHA ...

Read

Breaking Barriers: Women Shatter Stereotypes in Health and Safety The lack of gender diversity is an issue for many industries, and changing this has ...

Read

Top 10: OSHA Violations for 2023: Stay Compliant & Safe In the realm of occupational safety, staying abreast of the latest developments is ...

Read

In an industry that is often fast-paced, where the possibilities go beyond the traditional office setting, the demand for a field printer becomes a ...

Read

Workplace safety is not only crucial for protecting employees' well-being but also for the overall success of a business. Employers who invest in ...

Read

There are 12,900 worker-related injuries every day, according to the National Safety Council, and this equates to one injured person every 7 seconds. ...

Read

Workplace injuries are common occurrences. There are 12,900 worker-related injuries every day, according to the National Safety Council, and this ...

Read

In the world of industrial labeling solutions, one size certainly does not fit all. Different businesses and industries have unique label printing ...

Read

Safety is an essential aspect of any workplace. To ensure the well-being of employees and comply with regulations, businesses must implement ...

Read

It is no secret that noise plays a factor in day-to-day industrial manufacturing. Unfortunately, it is also one of the most pervasive occupational ...

Read

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing essential safety information. In environments ...

Read

The sounds of blaring horns and alarms fill your ears. Nothing is more insufferable or uninspiring than seeing the same boring signage every day or ...

Read

Creating compliant Occupational Safety and Health Administration (OSHA) safety signs is a crucial element in the overarching mission of fostering a ...

Read

Organizations are required under the OSHA General Duty clause to provide a working environment "free from recognized hazards that are causing or are ...

Read

Creating a safe work environment requires more than just following rules and providing training. It necessitates the active involvement and support ...

Read

Whether by force of nature or unfortunate accident, disasters can strike at any moment. In the workplace, disaster preparedness is crucial to ensure ...

Read

1,008 construction workers were killed in workplace accidents in 2020, 21% of all fatal occupational injuries. 368 from slips, trips, and falls 247 ...

Read

The undisputed champion continues its streak with year 12 at the top of the list. The standard outlines when and where fall protection is required ...

Read

71% believe their employers are not following through on safety promises

Read

450,000 people suffer burn injuries each year . Burns account for 42% of all workplace injuries . 20% of workplace burns result in hospitalization. ...

Read

As the calendar rolls over to 2023, sites that resolve to make safety a priority will have some new rules and regulations to incorporate. The Spring ...

Read

Personal protective equipment (PPE) related violations accounted for three of the top 10 most frequent OSHA citations in 2022. Protective clothing, ...

Read

Millions of U.S. workers are exposed to heat elements in their workplace each year. Hazardous heat exposure can occur both indoors, outdoors, and ...

Read

According to the Brain Injury Association, each year 2.8 million people sustain a workplace-related brain injury from: 48% falls

Read

88% of workers experience some burnout, with 60% reporting high levels of burnout* One-fifth will miss six or more workdays due to ...

Read

OSHA/ANSI Hardhat Requirements 68,000 injuries in 2020 required an absence from work 1,000 workers killed each year Only 16% of workers wore a hard ...

Read

One of the struggles of being in management is discovering new ways to engage employees in a way that encourages a positive safety culture. By ...

Read

Hearing loss happens slowly through years of exposure to loud noises. Here are some ways to help prevent noise hazards. Safety professionals spend ...

Read

In 2021, local fire departments responded to 1,353,500 fires in the US. That averages out to one every 23 seconds. These fires caused 3,800 civilian ...

Read

Workers face unique hazards on any jobsite that includes digging or trenching. According to the Bureau of Labor and Statistics: Workers face unique ...

Read

The undisputed champion continues its streak with year 12 at the top of the list. The standard outlines when and where fall protection is required ...

Read

Powerful machines are critical to industrial production, but they also pose severe hazards if not properly guarded. The National Institute for ...

Read

To help ensure color consistency for safety, the American National Standards Institute's (ANSI) Z535.1 brings its color code in line with the ...

Read

Some of the job hazards welders face each day are while working from heights, in extreme conditions, and in confined spaces. There are several simple ...

Read

Workplace injury incidents involving compressed air are still problematic. Employers can help ensure the safe use of compressed air by educating ...

Read

A near-miss reporting plan helps build a strong overall safety plan by reflecting on near misses and using the lessons learned to improve your ...

Read

According to OSHA, more than 6 million people work at roughly 250,000 construction sites throughout the United States on any given day. These ...

Read

The Occupational Safety & Health Administration (OSHA) is dedicated to ensuring the safety and well-being of 130 million workers throughout the ...

Read

Laser use in industry has seen a sharp increase in the past year and the technology is being used for a variety of applications. As the use of this ...

Read

Lean has been around for decades, but it still has its place as businesses evolve and retain vitality. Big companies' lean plans prove workers can be ...

ReadAccording to the Bureau of Labor Statistics, most of the workers in selected occupations who suffered impact injuries to the feet were not wearing ...

Read

On May 11, OSHA issued a final rule that requires employers to electronically submit injury and illness data to OSHA. To employers, this rule ...

Read

Create a safer work environment to reduce the likelihood of accidents on any oil and gas industry project using visual communication. Duralabel' ...

Read

Safety isn't the workplace enemy. There are many benefits that come from amplifying safety, and there are tools to make goals successful. Mention the ...

Read

How do you know if your safety signs are getting ignored? Conduct a self-audit to see where you can incorporate the following psychological ...

Read

Beer has never been a bigger business in the United States than it is today. The Brewers Association reported that small and independent brewers ...

Read

One of the biggest dangers police officers now face is now permanent hearing damage. Discharging firearms, sirens, and demonstrations are among the ...

Read

With a rampant rise in injuries from mining haulage equipment, MSHA and others are stepping up education, training, and other safety systems. With ...

Read

Headlines show that fatalities, injuries, and illnesses in the workplace are on a downward trend. Statistics for the last seven years prove this ...

Read

Partnership aimed at protecting construction workers from electrical hazards. OSHA renewed its alliance with the Independent Electrical Contractors ...

Read

To work with dust, it must be controlled. Keep dust collection systems in top working order as well. Otherwise, dust creates serious hazard risks. ...

Read

There is more to implementing Kaizen than we can include on a single web page. However, the following serves as an overview of introducing Kaizen ...

Read

Safety Inspection vs Safety Audit There's no one "right" way to assess the effectiveness of workplace safety programs. OSHA citations, days away from ...

Read

A confined space consists of any one of the following characteristics: Limited openings for entry and exit Unfavorable natural ventilation Not ...

Read

While data is still preliminary, OSHA's Top Ten Citation List for 2015 reveals trends in serious and willful violations. This news item covers the ...

Read

MSHA recently announced it will be enhancing how it enforces its "Rules to Live By" initiative, as well as the underground coal mine exam rule ...

Read

Does your workplace have a hearing protection program? Use these simple tips to improve worker hearing conservation and meet OSHA requirements. ...

Read

Eight years ago, OSHA established its Severe Violator Enforcement Program to target employers who heavily disregard to workplace safety laws. Each ...

Read

HVAC Installation Done Right: 8 Essential Tips to Prevent Costly Mistakes

Read

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational efficiency. Stocking the correct sizes, shapes, ...

Read

At DuraLabel, we are committed to providing safety solutions that are durable, reliable, and rigorously tested for compliance in the toughest ...

Read-1.png)

Directional pipe markers are key when it comes to effectively identifying a facility�s pipe system. These markers are vital communicators that safely ...

Read

In refrigeration and HVAC, it's out with old, complex systems and in with new, efficient ammonia systems. When working with low-charge ammonia ...

Read

Unlocking Safety and Efficiency: A Comprehensive Guide to Choosing the Right Industrial Label Printer In the complex ecosystem of industrial ...

Read

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and compressed air, which is crucial to ...

Read

Pipes serve as the glue to many sectors of the industrial industry by transporting water, oil, chemicals, and compressed air, which is crucial to ...

Read

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe infrastructure. Properly marked pipes provide ...

Read

Pipe marking quickly communicates essential information to everyone in a facility, improving overall workplace safety and productivity. The American ...

Read

Whether a pipe contains chemicals, water, or nothing, it's important to know if it's hazardous. ANSI/ASME A13.1-2020 clarifies how to label abandoned ...

Read

Workplace safety is more important than ever before. With federal rules and regulations in place and always changing, it's vital to run a workplace ...

Read

Pipe marker systems are an essential part of any water treatment facility. Effective pipe marker usage improves safety and increases efficiency by ...

Read

ANSI is the American National Standards Institute. It is a private organization involved with coordinating and publishing voluntary consensus ...

Read

For safe operations and maintenance, its important employees know what's inside the pipes they're working around to prevent accidental exposure to ...

Read

More businesses are embracing the benefits of dark manufacturing. See how a longtime business uses it and how to reinforce safety for workers. ...

Read

Imagine walking through a large facility filled with pipes running in every direction. These pipes carry important substances like water or ...

Read

Pipe marking quickly communicates information about a pipe and its contents, improving overall workplace safety and productivity. To get started with ...

Read

British Standard 1710 (BS 1710) provides a robust framework that fulfills the pipe marking requirements set forth in Health and Safety (Safety Signs ...

Read

Pipes can put people and facilities in danger if no one knows what's flowing through them. Pipe labels help provide essential information where it's ...

Read

The food warehousing industry is booming and companies are expanding their cold storage warehouses. These warehouses are sometimes kept at 65 degrees ...

Read

The Silver Eagle Refinery explosion released a tidal wave of broken glass. Homes were pushed off their foundations and countless workers were burned ...

Read

UK Pipe Marking When it comes to pipe marking in the United Kingdom (UK), there are two commonly cited authorities that many organizations turn ...

Read

Workplaces are safer than ever, but challenges remain: In 2014, nearly three million nonfatal workplace injuries were reported by private industry ...

Read

Artificial cooling systems keep industry running, and many of these systems use anhydrous ammonia as a refrigerant. How do these ammonia ...

Read

The heating, ventilation, air conditioning, and refrigeration industry is heating up as demand grows, new technology unfolds, and chemical changes ...

Read

Many of us romanticize the image of a wine maker caring for the vines, tending the fresh earth, hosting tastings paired with farm-fresh cuisine, and ...

Read

Simple tools like pipe marking can make a difference in efficiency for any facility. Workers, guests, and emergency responders need to know what is ...

Read

Workplace safety should always be at the forefront of your mind. Many recommendations exist on how to go about analyzing your workplace to ensure ...

Read

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical as the first. Systems are in place, ...

Read

At DuraLabel, we are committed to providing safety solutions that are durable, reliable, and rigorously tested for compliance in the toughest ...

Read

There are a lot of different hazards in the modern workplace. Between moving parts, vehicle traffic, ledges, low visibility, and pedestrian safety, ...

Read

To help ensure color consistency for safety, the American National Standards Institute's (ANSI) Z535.1 brings its color code in line with the ...

Read

Each year, nearly 80,000 private sector administrative workers suffer on-the-job injuries. With June named by the National Safety Council (NSC) as ...

Read

Electrical workers consider shocks as part of their job and normal, according to a study. However, it could signal that workers lack safety training. ...

Read

Pipe marking quickly communicates essential information to everyone in a facility, improving overall workplace safety and productivity. The American ...

Read

Whether a pipe contains chemicals, water, or nothing, it's important to know if it's hazardous. ANSI/ASME A13.1-2020 clarifies how to label abandoned ...

Read

Everyone knows arc flash is dangerous and the hazards that come with electrical work. However, sometimes simple mistakes are made, which can be ...

Read

Accidents will happen, and so can emergencies. As equipment and processes change, it's important to keep emergency plans updated too. Plan ahead to ...

Read

Whether used as a means to direct traffic, deter vehicle intrusions, and to protect people and structures, bollards act as visual guides, reminding ...

Read

There is no shortage of work for forklifts in material handling and other industries. Injuries and accidents involving forklifts can happen at any ...

Read

New chemicals are created every day for a variety of applications in industry. Working with chemicals and using them require careful adherence to ...

Read

There are hundreds of detailed resources on electrical safety. Most of them are written by (and for) electricians. But electricity is a part of daily ...

Read

National Forklift Safety Day is the second Tuesday in June. The day serves as a focal point for manufacturers to highlight safe use of forklifts and ...

Read

On Thursday, August 12, 2004, electrical contractor Donnie Johnson's day began like any other. However, the looming threat of Hurricane Charlie in ...

Read

Clearly labeled electrical conduit enhances workplace safety, boosts efficiency, and prevents costly mix-ups during maintenance and troubleshooting. ...

Read

Imagine walking through a large facility filled with pipes running in every direction. These pipes carry important substances like water or ...

Read

Forklifts and pedestrians in a busy workplace can sometimes lead to accidents. Yet, there are other important safety assessments that get overlooked. ...

Read

Winter weather brings unique challenges for professionals working in extreme conditions. Tower climbers and wind energy technicians face extreme ...

Read

In a recent Facebook poll, electrical workers said that work area and arc flash boundaries were among their top concerns. Here are a few tips to ...

Read

The Silver Eagle Refinery explosion released a tidal wave of broken glass. Homes were pushed off their foundations and countless workers were burned ...

Read

Military expectations are high when it comes to labeling products for MIL-STD-129 shipping and MIL-STD-130 asset management. Companies contracting ...

Read

To help solve mining work safety and health challenges, NIOSH continually researches best practices through its Intelligent Safety Technology for ...

Read

HVAC Installation Done Right: 8 Essential Tips to Prevent Costly Mistakes

Read

How Contractors Use Labels and Signs to Keep Job Sites Safe The final steps of a project are just as critical as the first. Systems are in place, ...

Read

Navigating the occupational safety and health environment can feel like wading through a minefield. When dipping your toes into regulations, a vital ...

Read

To help ensure color consistency for safety, the American National Standards Institute's (ANSI) Z535.1 brings its color code in line with the ...

Read

Some of the job hazards welders face each day are while working from heights, in extreme conditions, and in confined spaces. There are several simple ...

Read

Workplace injury incidents involving compressed air are still problematic. Employers can help ensure the safe use of compressed air by educating ...

Read

Create a safer work environment to reduce the likelihood of accidents on any oil and gas industry project using visual communication. Duralabel' ...

Read

How do you know if your safety signs are getting ignored? Conduct a self-audit to see where you can incorporate the following psychological ...

Read

Each year, nearly 80,000 private sector administrative workers suffer on-the-job injuries. With June named by the National Safety Council (NSC) as ...

Read

The Importance of the GHS When working with and storing hazardous chemicals, steps must be taken to ensure safety, in accordance with regulations ...

Read

Pipe marking quickly communicates essential information to everyone in a facility, improving overall workplace safety and productivity. The American ...

Read

As robotic workers join the warehouse industry, it is important to have safety signs and other communication to help protect the human workers who ...

Read

Everyone knows arc flash is dangerous and the hazards that come with electrical work. However, sometimes simple mistakes are made, which can be ...

Read

Accidents will happen, and so can emergencies. As equipment and processes change, it's important to keep emergency plans updated too. Plan ahead to ...

Read

Tunnels play a crucial role in modern infrastructure, providing passageways for vehicles, trains, and utilities beneath mountains, rivers, and even ...

Read

A list of safety supplies and other gifts that keep on giving for EHS managers. The holidays are here. Shopping yet for your favorite EHS manager? ...

Read

There are clear guidelines that health care and lab workers must follow when handling biohazardous waste. Proper management and disposal of materials ...

Read

As the weather cools down, workers need ways to heat up. Options include propane warming stations, space heaters, fireplaces, and wood or coal ...

Read

A UN panel has made an update to its Globally Harmonized System of Classification and Labeling of Chemicals. To help employers figure out what needs ...

Read

When done efficiently, safety signs warn workers of potential hazards to avoid injuries in the workplace. From arc flash warning signs and OSHA ...

Read