DuraLabel�s Tough-Tested Process: Raising the Bar for Label Durability

11

June,

2024

2 MINUTE READ

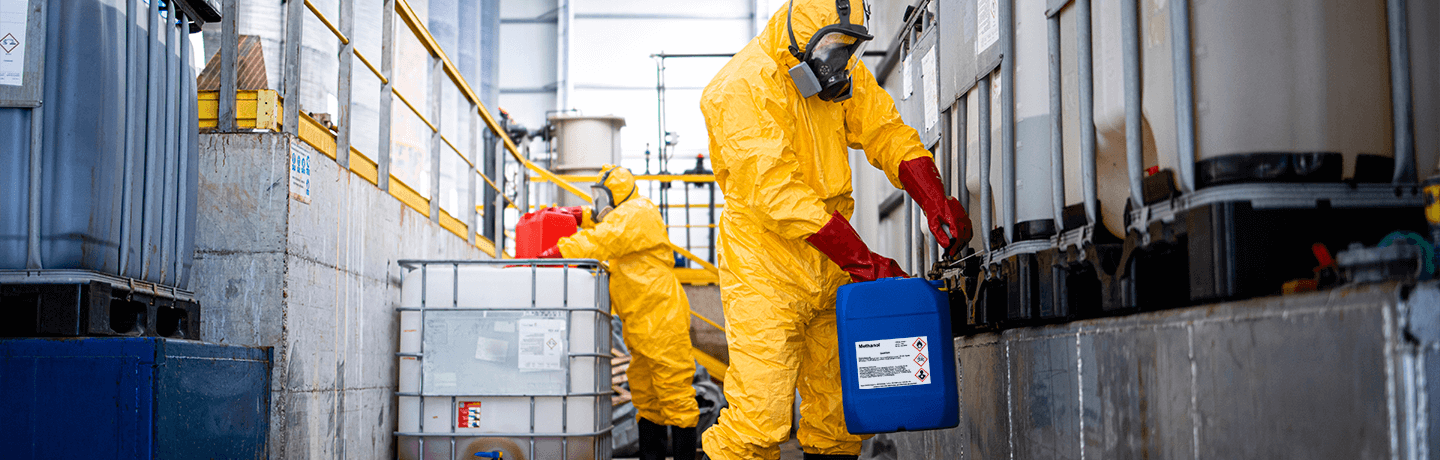

At DuraLabel, we are committed to providing safety solutions that are durable, reliable, and rigorously tested for compliance in the toughest conditions. Our testing process is designed to ensure that every label, sign, and floor marking product can withstand tough environments, from extreme weather conditions to chemical exposure.

Why We Test In-House

Key benefits of DuraLabel�s in-house testing process:

- Control and Flexibility: Direct oversight of testing procedures ensures they meet the unique requirements of our products. For example, we replicate industrial environments by exposing labels to intense heat and cold in temperature-controlled chambers, guaranteeing reliable performance in manufacturing and outdoor settings.

- Faster Turnaround: On-site testing delivers quick results and swift resolutions to potential issues. For instance, when designing a new floor marking tape, we can immediately test its durability by repeatedly driving a forklift over it to simulate warehouse traffic and enable fast adjustments if necessary.

- Consistency and Standardization: Our standardized testing methods guarantee uniformity and reliability across all products. For instance, chemical-resistant labels are exposed to harsh solvents like acetone and alcohol to ensure they remain legible in facilities handling hazardous materials.

- Enhanced Expertise: Our in-house testing team continually improves methods and provides invaluable insights into product performance. By running abrasion tests with machinery parts frequently handled by workers, we ensure labels can withstand friction and remain intact.

- Integrated Development Process: Close collaboration between testing and product development teams integrates feedback directly into our design and quality assurance processes.

By simulating scenarios like heavy equipment contact, chemical spills, and environmental stress, our testing process ensures DuraLabel products meet the rigorous demands of real-world demands. This commitment to quality delivers top-performing labels and signs while fostering continuous improvement in our manufacturing processes.

How DuraLabel�s In-House Testing Compares with Industry Standards

DuraLabel's testing processes don�t just meet industry standards�they raise the bar. While many manufacturers rely on generic certifications or outsourced testing, DuraLabel takes a direct, hands-on approach.

Adhesion Testing

Industry standards, like UL 969, require labels to adhere under controlled conditions, often involving set temperatures and smooth surfaces. DuraLabel testing goes beyond these requirements by simulating real-world challenges, such as high-impact vibrations from heavy machinery and exposure to grease and oil. For example, DuraLabel tests labels on uneven and textured surfaces commonly found in manufacturing environments to verify adhesion under harsher conditions.

Chemical Resistance Testing

The ASTM Standards for Label Durability focus on wear and tear, often testing resistance to a small range of chemicals. DuraLabel expands on these tests by exposing labels to a broader set of substances, including industrial solvents, cleaners, and harsh chemicals like acetone and sulfuric acid. This ensures the labels remain legible and durable even in industries like food processing and automotive manufacturing, where chemical exposure is common.

Pipe Marking Compliance

DuraLabel adheres to ANSI/ASME A13.1 for pipe labeling, which sets the standard for the size, color, and placement of pipe markers for safety and compliance. DuraLabel�s tough-tested pipe markers are evaluated for legibility, adhesion, and fade resistance in industrial settings, ensuring clear communication of hazards and pipe contents over time.

By exceeding industry requirements, DuraLabel delivers products that perform in scenarios where other labels might fail. Whether exposed to harsh chemicals or extreme weather, DuraLabel ensures your facility�s signage remains clear and durable, even in the toughest conditions.

The Benefits of Tough-Tested Products

Tough-tested products are more than just labels�they�re a long-term investment in your facility�s safety and efficiency. Here's how our testing delivers real benefits for your business:

- Cost Savings: Tough-tested labels are proven to last longer, reducing maintenance costs and minimizing the need for frequent replacements. This leads to fewer operational interruptions and less downtime.

- Risk Mitigation: Low-quality signs and labels can result in miscommunication, workplace accidents, legal issues, and Occupational Safety and Health Administration (OSHA) violations. Tough-tested labels resist wear and remain clear and legible in harsh conditions, helping prevent costly fines and accidents.

- Improved Workplace Efficiency: Reliable labels minimize confusion and delays, allowing employees to quickly locate tools, materials, and safety information. This streamlines workflows and reduces time wasted due to unclear or missing labels.

- Reduced Environmental Impact: Durable labels require fewer replacements, resulting in less waste over time. By using tough-tested labels, businesses contribute to sustainability efforts by minimizing discarded materials and packaging.

- Compliance Assurance: Under

RELATED RESOURCES

Label Printer Systems for Challenging Outdoor Environments

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing ...

Read

Signs That Stick: The Importance of Industrial Grade Label Adhesives

Considering the Chemistry of Surface Adhesion The International Union of Pure and Applied Chemistry (IUPAC), ...

Read

Choosing the Right Industrial Label Printer for Your Business Needs

In the world of industrial labeling solutions, one size certainly does not fit all. Different businesses and ...

Read