TPM is the concept of self-directed maintenance updated, wherein machine operators are responsible for the routine maintenance and operations of their machines and equipment.

TPM is the concept of self-directed maintenance updated, wherein machine operators are responsible for the routine maintenance and operations of their machines and equipment.

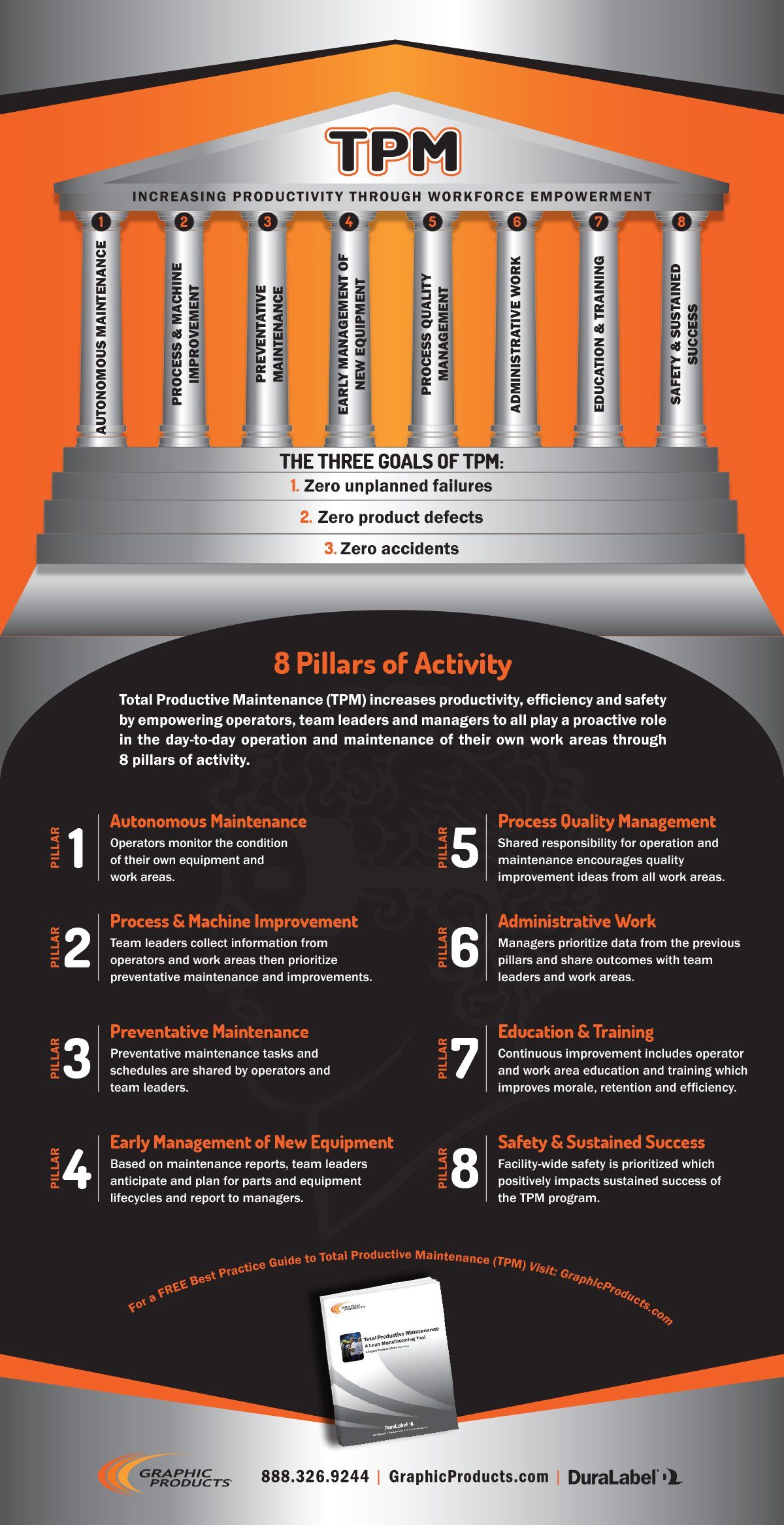

The following is a transcript of the Pillars of TPM Infographic:

Increasing productivity through workforce empowerment

1. Autonomous Maintenance

2. Process & Machine Improvement

3. Preventative Maintenance

4. Early Management of New Equipment

5. Process Quality Management

6. Administrative Work

7. Education & Training

8. Safety & Sustained Success

1. Zero unplanned failures

2. Zero product defects

3. Zero accidents

Total Productive Maintenance (TPM) increases productivity, efficiency, and safety by empowering operators, team leaders and managers to all play a proactive role in the day-to-day operation and maintenance of their own work areas through 8 pillars of activity.

Pillar 1: Autonomous Maintenance

Operators monitor the condition of their own equipment and work areas.

Pillar 2: Process & Machine Improvement

Team leaders collect information from operators and work areas then prioritize preventative maintenance and improvements.

Pillar 3: Preventative Maintenance

Preventative maintenance tasks and schedules are shared by operators and team leaders.

Pillar 4: Early Management of New Equipment

Based on maintenance reports, team leaders anticipate and plan for parts and equipment lifecycles and report to managers.

Pillar 5: Process Quality Management

Shared responsibility for operation and maintenance encourages quality improvement ideas from all work areas.

Pillar 6: Administrative Work

Managers prioritize data from the previous pillars and share outcomes with team leaders and work areas.

Pillar 7: Education & Training

Continuous improvement includes operator and work area education and training which improves morale, retention, and efficiency.

Pillar 8: Safety & Sustained Success

Facility-wide safety is prioritized which positively impacts sustained success of the TPM program.

For a FREE Best Practice Guide to Total Productive Maintenance (TPM) visit: GraphicProducts.com

The following is a transcript of the Pillars of TPM Infographic:

Increasing productivity through workforce empowerment

1. Autonomous Maintenance

2. Process & Machine Improvement

3. Preventative Maintenance

4. Early Management of New Equipment

5. Process Quality Management

6. Administrative Work

7. Education & Training

8. Safety & Sustained Success

1. Zero unplanned failures

2. Zero product defects

3. Zero accidents

Total Productive Maintenance (TPM) increases productivity, efficiency, and safety by empowering operators, team leaders and managers to all play a proactive role in the day-to-day operation and maintenance of their own work areas through 8 pillars of activity.

Pillar 1: Autonomous Maintenance

Operators monitor the condition of their own equipment and work areas.

Pillar 2: Process & Machine Improvement

Team leaders collect information from operators and work areas then prioritize preventative maintenance and improvements.

Pillar 3: Preventative Maintenance

Preventative maintenance tasks and schedules are shared by operators and team leaders.

Pillar 4: Early Management of New Equipment

Based on maintenance reports, team leaders anticipate and plan for parts and equipment lifecycles and report to managers.

Pillar 5: Process Quality Management

Shared responsibility for operation and maintenance encourages quality improvement ideas from all work areas.

Pillar 6: Administrative Work

Managers prioritize data from the previous pillars and share outcomes with team leaders and work areas.

Pillar 7: Education & Training

Continuous improvement includes operator and work area education and training which improves morale, retention, and efficiency.

Pillar 8: Safety & Sustained Success

Facility-wide safety is prioritized which positively impacts sustained success of the TPM program.

For a FREE Best Practice Guide to Total Productive Maintenance (TPM) visit: GraphicProducts.com

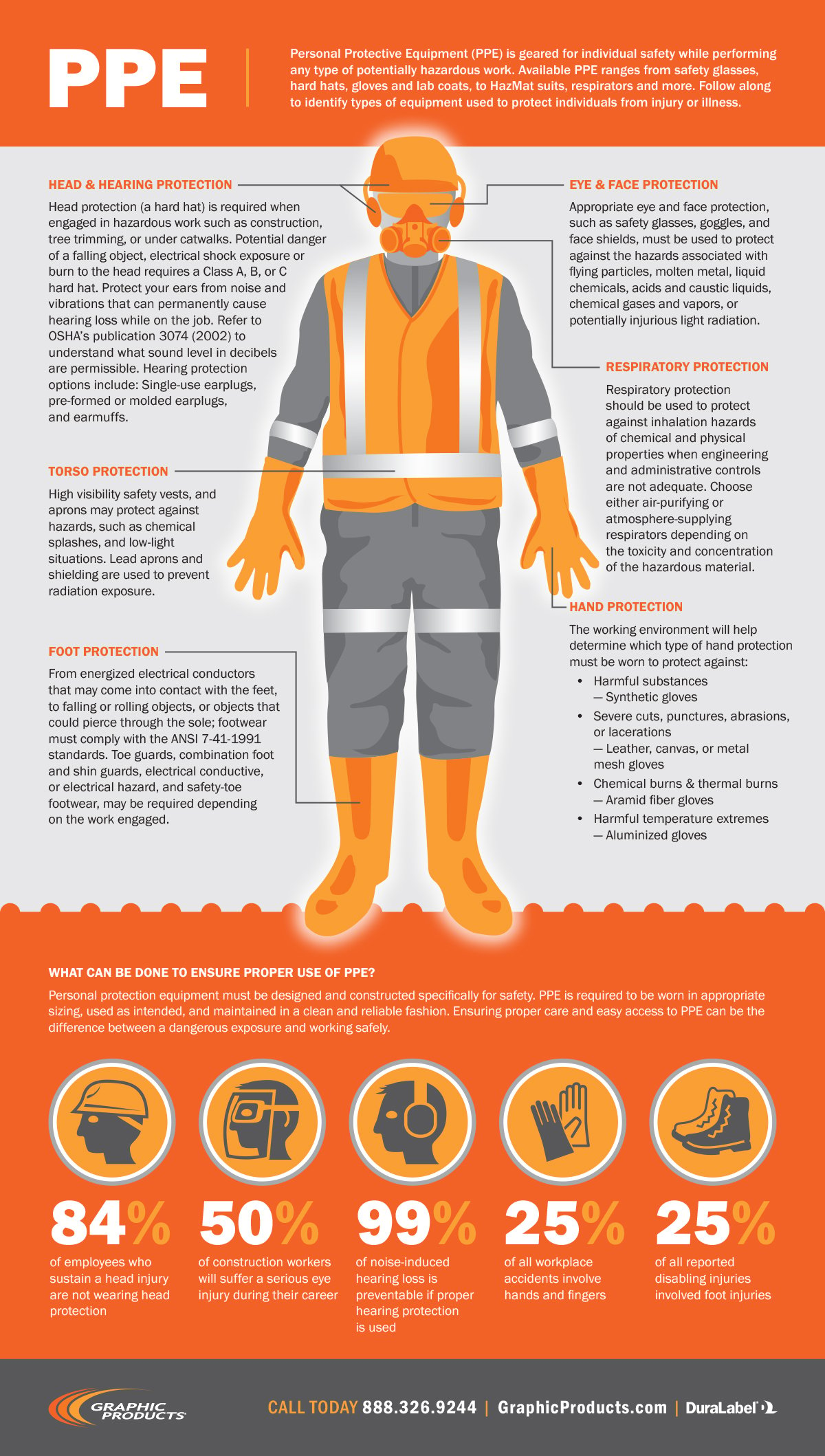

The following is a transcript of the PPE Infographic: Personal Protective Equipment (PPE) is geared for ...

Read

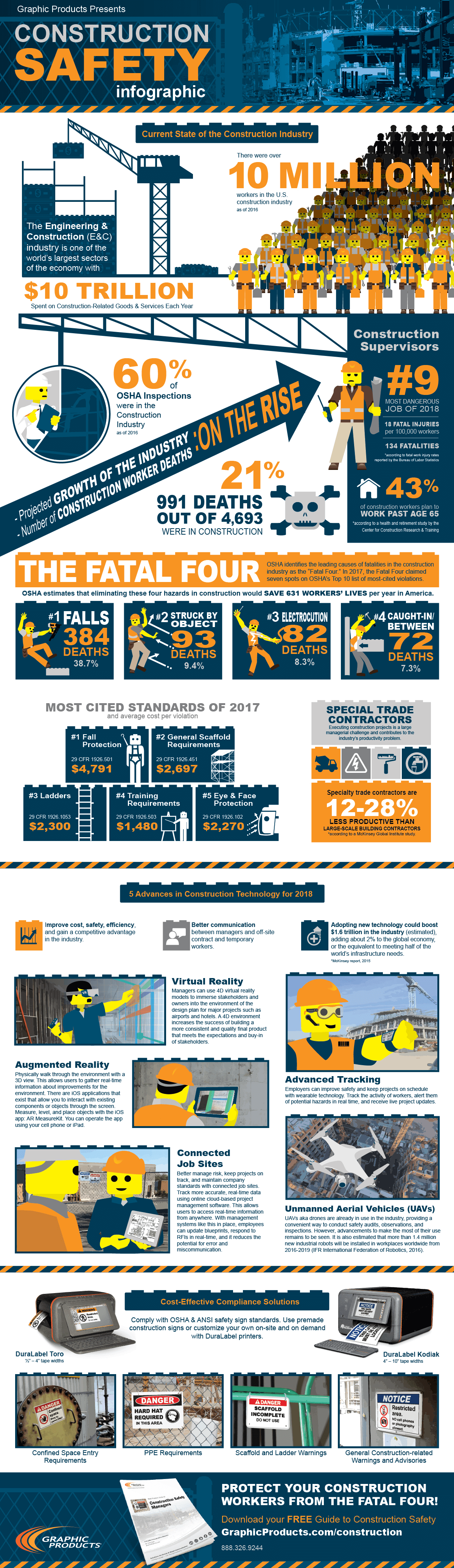

The following is a transcript of the Construction Safety infographic: Construction Safety Infographic Current ...

Read

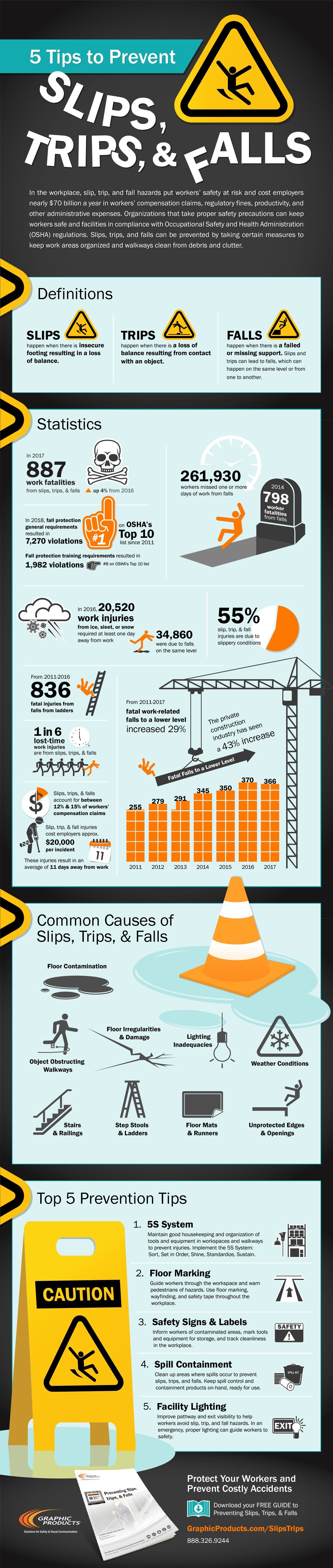

The following is a transcript of the 5 Tips to Prevent Slips, Trips, & Falls infographic: 5 Tips to ...

Read